Newest FAQs

Yes! Quantities of bolts can be misinterpreted as bolt diameters from construction plans. Reasons quantities are misinterpreted? One of the most frequent ways we see this mix-up is when a detailer specs out a quantity per a specific location for a particular bolt. Detailers will go through and label where bolts need to be located... Read more

When tightening a nut onto anchor bolts, it is important to follow procedures to ensure proper installation and secure fastening. Here is a general outline: Clean the threads of any debris or rust using a wire brush or similar tool. If specified apply wax to threads and bearing surfaces. Place the nut on the anchor bolt and hand-tighten... Read more

The short answer is yes. Here is why: When bolts go through the hot-dip galvanizing process the zinc leaves an extra layer coating the bolt. This extra layer of zinc adds 0.002” – 0.006” of thickness to the bolt. When galvanized nuts are manufactured their threads are tapped oversize to accommodate for the thicker material. ... Read more

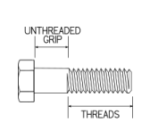

Fully threaded bolts are often referred to as “tap bolts”. The unthreaded portion of a bolt is often referred to as the “grip”. ASME B18.2.1 is the dimensional standard that covers hex, heavy hex, and square head bolts as well as lag screws. This specification states for fully threaded bolts and lag screws that are... Read more

The length of a tie rod assembly is typically measured from pin to pin, which is the centerline of the pin of one clevis to the centerline of the pin of the opposing clevis. However, when you are looking to order a tie rod assembly you will need to know additional dimensions. What information is... Read more

With Portland Bolt and Manufacturing Company located in the Northwestern part of the United States, you may ask yourself why Portland Bolt would be the best source for your fastener requirement versus a multitude of companies that deal in the fastener industry. Although geographic location is a factor when choosing a fastener supplier, Portland Bolt... Read more

Lag screws are used in wood and are installed by rotating the head to screw the lag screw into the wood. Since lag screws are designed to drive into the wood instead of being secured with a nut they have deeper and sharper threads than your average hex-headed bolt which typically uses UNC (national course)... Read more

When stainless steel fasteners are specified in the construction industry, 304 and 316 stainless steel are by far the most common. Although 304 and 316 are simply the type of stainless raw materials used to produce a finished fastener to an ASTM specification, it is also common for the finished fastener to be specified as... Read more

The short answer is no, they don’t need to be galvanized but they can be. In some cases, they should be. You’ll want to consider galvanized anchor bolts if they are going to be in a corrosive environment or exposed to the weather. Galvanizing anchor bolts provide corrosion resistance to the bolt. Instances where it... Read more

There are a variety of configurations of anchor bolts and anchor rods, such as headed anchor bolts, bent anchor bolts, thread each-end rods, and fully threaded rods. When an anchor rod is specified, it is most likely a rod with threads on each end or a fully threaded rod. If the rod has threads on... Read more