What should you know about Lag Screws before ordering?

Lag screws are used in wood and are installed by rotating the head to screw the lag screw into the wood. Since lag screws are designed to drive into the wood instead of being secured with a nut they have deeper and sharper threads than your average hex-headed bolt which typically uses UNC (national course) threads.

Screw vs. Bolt

Lag screws are often called lag bolts. This term is technically incorrect because bolts are used with a nut to secure them in place. A screw is driven into the material it is holding together which is typically wood and does not have a nut securing it in place.

Size and Grade

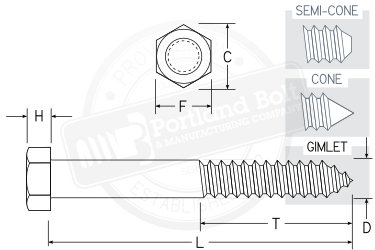

The two critical dimensions when ordering lag screws are the diameter of the lag and the length measured from the underside of the head. Most lag screws are ordered under the ASTM A307 Grade A specification which is made from a low-strength, mild steel. Occasionally high strength lag screws are required, so check your plans and specifications for the correct grade.

Thread Length Formula

Most imported lag screws and domestically manufactured lag screws will possess a thread length based on the following formula:

The minimum thread length shall be equal to one-half the nominal screw length plus 1/2″ or 6”, whichever is less.

For extremely long lag screws or for specific applications, custom lag screws with extended threads may need to be manufactured.

Pointing

There are three kinds of points a lag screw can have. These points are cone, semi-cone, and gimlet. Semi-cone points are the standard point Portland Bolt uses when manufacturing lag screws. The gimlet point is typically reserved for only small-diameter bolts because they typically don’t require a pilot hole to be drilled prior to installation.

Gimlet points are unnecessary for larger-diameter lag screws because they require a pilot hole to be drilled prior to installation. This is because there would be too much torque required to screw in larger diameter lag screws without a pilot hole.

Heading

Lag screws can either come as hex-headed or square-headed. These options both have the same strength and mechanical properties. Hex-headed lag screws are standard.

The reason someone would want a square-headed lag screw is for aesthetic purposes or to create a rustic look. Square heads used to be standard in construction-grade fasteners until the mid-1900s.

Pilot Holes

A pilot hole is a pre-drilled hole for the lag screw prior to installation. This is used with larger-diameter lag screws because it would require too much torque to screw in a larger-diameter lag screw without the pilot hole.

The pilot hole is typically slightly smaller in diameter than the root of the threads. This is done to make installation easier while still facilitating the proper connection between the lag screws and wood. An engineer should be consulted for questions regarding specific sizing and applications of pilot holes.

Stock

Portland Bolt regularly manufactures and stocks screws. We are able to manufacture lag screws from ½” to 1½” in diameter in virtually any length. However, we do stock many sizes of imported lag screws with gimlet points.

Diameters: 1/2″ – 3/4″

Grade: ASTM A307

Lengths: 20″ maximum

Origin: Import

Finish: Plain and hot-dip galvanized

| Length (in.) | Diameter | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 3/8" | 1/2" | 5/8" | 3/4" | 1" | ||||||

| Plain | Galv. | Plain | Galv. | Plain | Galv. | Plain | Galv. | Plain | Galv. | |

| 1 | 11375 | 11376 | - | - | - | - | - | - | - | - |

| 11⁄4 | 11377 | 11378 | - | - | - | - | - | - | - | - |

| 11⁄2 | 11379 | 11380 | 18904 | 18905 | - | - | - | - | - | - |

| 13⁄4 | 11381 | 11382 | - | - | - | - | - | - | - | - |

| 2 | 11383 | 11384 | 11413 | 11414 | 11447 | 11448 | - | - | - | - |

| 21⁄2 | 11385 | 11386 | 11415 | 11416 | 11449 | 11450 | - | 19575 | - | - |

| 3 | 11387 | 11388 | 11417 | 11418 | 11453 | 11454 | 11489 | 11490 | - | - |

| 31⁄2 | 11389 | 11390 | 11419 | 11420 | 11455 | 11456 | 11491 | 11492 | - | - |

| 4 | 11391 | 11392 | 11421 | 11422 | 11457 | 11458 | 11493 | 11494 | - | - |

| 41⁄2 | 11393 | 11394 | 11423 | 11424 | 11459 | 11460 | - | - | - | - |

| 5 | 11395 | 11396 | 11425 | 11426 | 11461 | 11462 | 11497 | 11498 | - | - |

| 51⁄2 | 11397 | 11398 | 18906 | 18907 | 18908 | 18909 | - | - | - | - |

| 6 | 11399 | 11400 | 11429 | 11430 | 11465 | 11466 | 11501 | 11502 | - | - |

| 7 | 11403 | 11404 | 11433 | 11434 | 11469 | 11470 | 11505 | 11506 | - | - |

| 8 | 11407 | 11408 | 11437 | 11438 | 11471 | 11472 | 11509 | 11510 | - | - |

| 9 | - | - | 11439 | 11440 | 11473 | 11474 | 11511 | 11512 | - | - |

| 10 | 11411 | 11412 | 11441 | 11442 | 11475 | 11476 | 11513 | 11514 | - | - |

| 11 | - | - | - | - | 18910 | 18911 | 18913 | 18914 | - | - |

| 12 | 18902 | 18903 | 11445 | 11446 | 11479 | 11480 | 11517 | 11518 | - | 17140 |

| 14 | - | - | 18266 | 18267 | 11481 | 11482 | 11521 | 11522 | - | - |

| 16 | - | - | 18268 | 18269 | 19597 | 19545 | 11525 | 11526 | - | - |

| 18 | - | - | 18270 | 18271 | 19693 | 19694 | 11529 | 11530 | - | - |

| 20 | - | - | - | - | - | - | 18915 | 18916 | - | - |

| These sizes are readily available in the marketplace and Portland Bolt stocks many of them in varying quantities. If you require a size that is not listed, Portland Bolt will manufacture them. | ||||||||||

Manufacturing

The process of manufacturing lag screws is extremely similar to the process of manufacturing standard hex-headed bolts. The key differences are the tooling used in the threading and pointing process.

Cutting

The first stage of the manufacturing process is cutting the 20’ round bar we stock to the proper length required to manufacture your lag screw. In most cases, this is typically done by shearing the material. For small quantity runs or extremely long lengths, this is achieved by saw cutting.

Threading

For lag screws, the threading process consists of using special chasers to cut the threads needed for the lag screws. Cut threading is the process of cutting away the excess steel to create the threads.

Heading

The heads of the lag screws are hot forged. This is the process of heating the end of the steel round bar and using an upsetter to forge the steel into the correct shape, typically hex or square. This is also the stage where the proper head markings are applied.

Pointing

While this is the stage normal hex-headed bolts would be chamfered, lag screws are taken to get a semi-cone point. A semi-cone point will allow easy insertion of the lag screw into the pilot hole. While this was covered earlier, cone and gimlet points are generally unnecessary for lag screws since in most cases pilot holes are required to install the lag screw.

Galvanizing

Lag screws that will be exposed to the elements are often galvanized to provide corrosion resistance. Galvanizing lag screws is the process of metallurgically bonding zinc to the steel and is performed in Portland Bolt’s 140,000-square-foot manufacturing facility.

We need Lag Screws. Going into barn beams.

1 inch in diameter and 4 1/2 inch long. Quantity of 34

3/8 inch in diameter and 4 inches long. Quantity of 32

3/8 inch in diameter and 3 inches long. Quantity of 22

Standard

ASTM A307 Grade A

@Cecil- one of our salespeople will contact you shortly.