How are Threaded Anchor Rods Used in Concrete?

There are a variety of configurations of anchor bolts and anchor rods, such as headed anchor bolts, bent anchor bolts, thread each-end rods, and fully threaded rods. When an anchor rod is specified, it is most likely a rod with threads on each end or a fully threaded rod.

If the rod has threads on each end, it will usually have a nut on the embedded end and will often be accompanied by an anchor plate which provides a larger bearing surface to increase pull-out strength in the concrete foundation. A fully threaded anchor rod may be used with the same hardware as a rod with threads on each end or they will have top hardware and the embedded portion will be held in with epoxy.

Anchor rods are used in concrete construction to provide a secure and reliable means of attaching structural components to a concrete foundation. As stated above, threaded anchor rods are normally threaded on each end or fully threaded. The most common difference between these two products is how they are installed.

Rods with threads on each end are normally cast-in-place, whereas fully threaded rods are post-installed. Although both types essentially perform the same function, the configuration will differ depending on the application. The following information will lay out the differences between cast-in-place anchor rods and post-installed anchor rods.

What are Cast-In-Place Anchor Rods?

Cast-in-place anchor rods are cast in wet concrete before the concrete sets. Normally, the anchor rod will be installed in the foundation when the concrete is poured, only leaving the projecting thread of the anchor rod exposed.

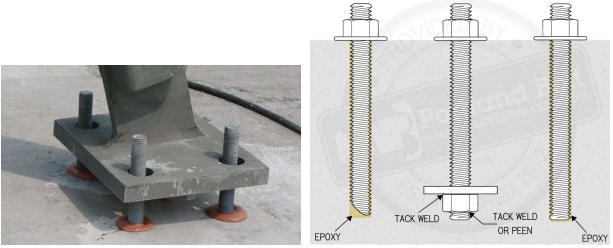

A cast-in-place anchor rod with threads on each end will normally have an assembled nut, sometimes accompanied by an anchor plate, on the embedded end helping to keep the rod from pulling out of the concrete.

It is also common to have two nuts “sandwiching” a flat washer (or plate), an embedded template with a bolt pattern matching the pole or steel column that the rods are anchoring, or all of the above. Cast-in-place anchors are normally used when large embedment lengths and high tensile strengths are required for a given load.

What are Post-Installed Anchor Rods?

Post-installed anchor rods are anchor rods installed after the concrete base has been set. A hole is drilled into the concrete and the anchor is then installed into the hole.

Anchor rods used in this way are often referred to as epoxy anchors or adhesive anchors. The reason that they are named either epoxy or adhesive anchor rods is that they are placed in a pre-drilled hole, which contains an epoxy that dries and bonds to the anchor rod thread as well as to the concrete.

Epoxy anchors are capable of reaching high bond-stress values in relatively fast cure times. Epoxy anchors are fully threaded rods that can be supplied in many different grades and finishes and can be cut to any length required for a given application.

Why use a rod with threads on each end or a fully threaded rod?

There are a variety of reasons why an anchor rod with threads on each end or a fully threaded rod would be preferred. An anchor rod with threaded ends is likely used prior to the concrete being poured whereas a fully threaded rod will be used after the foundation has been set, possibly due to an error where a pole or a steel column may need to be moved.

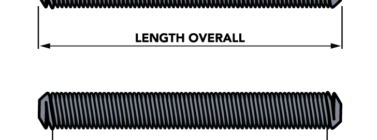

Handrails and other small structures are often installed on preexisting concrete foundations using epoxy anchors. Another reason for a fully threaded rod to be used is that the fully threaded body provides additional resistance from the risk of pulling out. The most common reason why one configuration would be preferred over the other is due to availability. A rod with threads on each end will likely need to be manufactured from scratch, whereas a fully threaded anchor rod can simply be cut to length from a mass-produced 10’ or 12’ length.

When a rod with threaded ends is produced, the process is simple. The length of the rod is cut from a 20-foot and it is then threaded on both ends. Although there are certain diameters and lengths of anchor rods that are commonly used, resulting in them being available in stock, they will most likely need to be custom-made due to the countless sizes that may be required.

The manufacturing process is about as basic as it comes in regards to custom anchor bolts, but it does require some lead time. A fully threaded rod, however, may be stocked in six, ten, or twelve-foot sticks, and simply needs to be cut to whatever length the project requires. This is usually the preferred choice when the anchor rod is needed immediately to keep the project on schedule.

can you tell me which will have larger resistance when we have headed threaded bolt vs J-bolt with same grade, embedment, size etc.

@Ying- We don’t have the specific pull out values on hand for both types, but we have seen the industry shift to headed bolts from bent ones, which leads us to assume that those are preferred in most applications.