How much thread length will I need on the tie rods I am ordering?

Unlike hex bolts, lag screws, and structural bolts, there is no standard thread length for tie rods. A detailer or engineer may specify the thread length for tie rods, but it is not uncommon for the thread length to be left unspecified. When thread lengths are not specified, Portland Bolt will determine the thread length in order to provide the potential for full engagement into the turnbuckles and clevis ends.

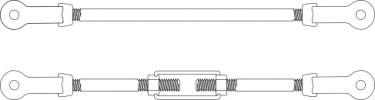

Tie rods, also referred to as sag rods or tension rods, typically consist of a threaded rod with reverse thread on the ends that are assembled with matching clevises. Another common tie rod configuration may include a turnbuckle in the center. Both configurations are shown in the illustration below.

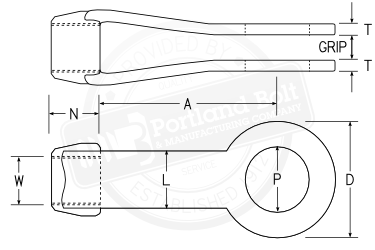

Determining the maximum amount that a threaded rod can penetrate into a clevis or turnbuckle will depend on the length of the turnbuckle and clevis number and the pin diameter. Clevises come in sizes from #2 – #8 and the sizes are functions of the compatible tap/pin combinations. Clevis pins, “P” dimension below, pass through the clevis and a steel knife plate in order to fasten the tie rod to the connection point. Half of the clevis pin diameter is included in the “A” dimension below so the general equation that Portland Bolt will use to calculate thread length is as follows:

Thread = “N” + “A”- (.5 x “P”)

For example, if Portland Bolt is calculating the amount of thread length that should be added to ¾” diameter tie rods that would be assembled with #2½ clevises and ¾” diameter pins, the calculation would be:

1” + 4” – (.5 x ¾”) = 4-5/8” thread length

Portland Bolt may choose to round the thread length up to the nearest ½” increment. In the example above, Portland Bolt may choose to thread the ¾” diameter rods with 5” of thread on each end so full clevis engagement can be achieved.

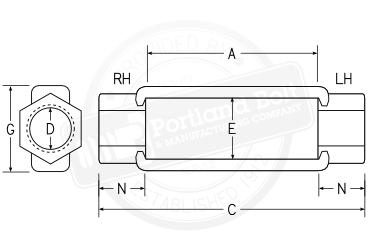

An important consideration for thread length on tie rods is determining whether there is enough thread length for a turnbuckle, if one is being used. Turnbuckles are most common with a 6” take-up, but depending on the diameter, they may be available with 9”, 12”, 18”, 24”, or 36” of take-up. According to our Tie Rod Calculator, each rod will engage ¼ of the length of the turnbuckle. This means for 6” turnbuckles, a rod would assemble 1.5” on each end leaving 3” for adjustment on the center. Our Formula for determining thread length for turnbuckles would be:

Thread = “N” + (.5 x “A”)

For example, if Portland Bolt is calculating the amount of thread length that should be added to ¾” diameter tie rods that would be assembled with a 12” turnbuckle, the calculation would be:

1-1/16” + (.5 x 12”) = 7-1/16” thread length

Clevis thread lengths will always meet or exceed the amount of thread required to fully engage into 6” turnbuckle. However, for longer turnbuckles, the thread length may need to be longer for the turnbuckle ends in order to allow for complete engagement. In the examples listed above for clevis and turnbuckle thread length, the turnbuckle end would actually require more thread than the clevis end in order to allow for complete engagement.

For more information on tie rod assemblies, see portlandbolt.com/products/rods/tie-rods/ or tierodassemblies.com