Newest FAQs

The ASTM A307 specification does not provide any washer recommendations to go with fasteners specified to A307 grades A or B. Most commonly, a simple F844 flat washer is used with A307 fasteners. F844 washers have a larger outside diameter than F436 hardened washers. Since the A307 specification doesn’t recommend what to use, any washer... Read more

SAE J429 Grade 5 falls under the SAE International specification, formerly known as the Society of Automotive Engineers. While similar in function to ASTM, it is the scope of their standards that is different. SAE has a more narrowly focused range of standards. Original Equipment Manufacturers (OEMs) tend to use more bolts manufactured to SAE... Read more

Anchor bolts come in several different configurations, such as 90-degree bent, headed, rods with threads on each end, or fully threaded rods to name a few. Anchor bolts can be made in many grades. shapes and sizes, however, there are two distinct categories of anchor bolts: post-installed anchors and cast-in-place anchors. Although both types essentially... Read more

The rotational capacity test, sometimes referred to as a ROCAP test or RC test, serves as a quality control measure to ensure that high-strength structural bolt assemblies will function together as a unit to achieve the required preload (clamping force) without experiencing thread stripping, galling, or premature failure. Per the ASTM F3125 specification, the test... Read more

When Portland Bolt calculates the length of the rods in a tie rod using the pin-to-pin length of the assembly, we assume that the rods will be threaded into the clevises the full length of the female threaded nut component (Dimension ‘N’ in the drawing below) plus an additional length equal to ½” or half... Read more

When looking at a bolt specification, you may notice that some are ASTM standards, such as ASTM F1554, and some are SAE standards, such as Grade 5 (a common bolt found within the SAE J429 specification). Outside the technical differences (mechanical requirements, chemical requirements, and other requirements) that vary between any fastener standard, the difference... Read more

The use of stainless nuts with galvanized bolts is not advisable. Portland Bolt has fielded requests for galvanized bolts that have a stainless nut and washer as the hardware. Ideally, you would use a galvanized nuts and washers with a galvanized bolts and stainless bolts with stainless nuts and washers. Both types of nuts and... Read more

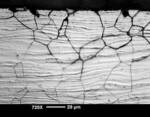

In order to answer this question, we must first define what intergranular corrosion is. It is a type of corrosion where the grain boundaries of crystallites in austenitic steel are more susceptible to corrosion than the inside of the material. Grain boundaries can become depleted during the manufacturing of stainless steel round bar, the hot... Read more

Type 304 and Type 316 are very common stainless steel grades that just refer to a type of stainless steel. If you were to look for Type 304 or 316 stainless steel bolts in the ASTM Fastener Standards Manual you aren’t going to find them. That is because they are steel grades as opposed to... Read more

No. The specification moves up in 1/8” increments starting at ½” diameter and maxing out at 1-1/2”. Under the old A325 – 09 specification, there was a reference about oversize limits on bolts and listed 9/16” diameter as a size. Since A325 bolts have been reclassified under the new F3125 specification, there is no longer... Read more