How Do You Cut All Thread Rod?

Fully threaded rods can be supplied by several different manufacturing methods depending on the job’s requirements.

What is all thread rod?

All thread rod is a piece of steel round bar that is threaded across its entire length. They are used for a wide variety of purposes, from through bolts to concrete anchors. It might also be called fully threaded, continuously threaded, redi-rod, or a stud – though technically a stud is a distinct type of fastener from a piece of all-thread rod.

Difference between all thread rod and a fully threaded stud

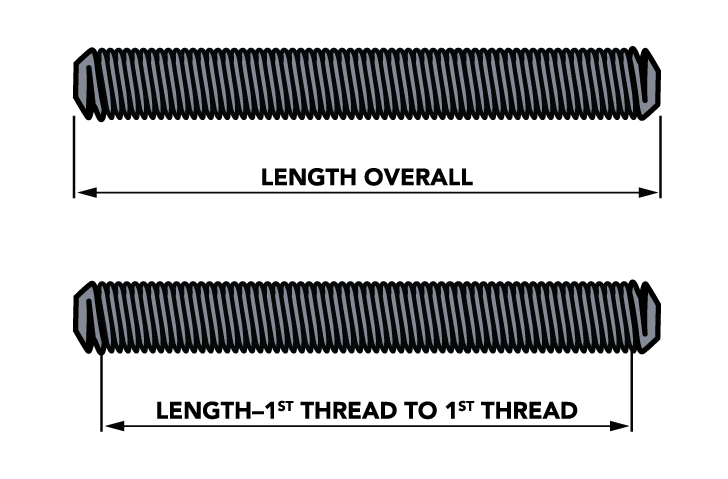

The basic difference is that while all thread rod has their length measured from “end-to-end”, studs are measured from “first-to-first”.

End-to-end length is what you would get if you measured the overall length of the rod, while first-to-first measures specifically from the first full thread on one end of the rod to the first full thread on the other end of the rod, making the overall length of a fully threaded stud slightly longer than the overall length of all thread rod.

All the information below applies equally to all thread rods as it does to studs.

Full Length

Commercially available all thread comes stocked in either twelve-foot or ten-foot lengths. These are typically made with rolled threads. Often times these rods are not stamped or marked per the specification of the bolt grade to which they are being certified. This is because in their long commercial lengths, they are considered raw material and not yet a finished fastener.

End users do not always know the correct cut lengths required for the job beforehand and request the full-length rod so they can cut the rod on site to the proper length. In this case, the rods should be stamped or marked on site per the bolt specification to which they will be certified.

Cut to Length

More often the customer knows the length to which each rod must be cut beforehand. In this case, they can order the rods from the supplier already cut, chamfered, and stamped per the bolt specification to which the rod is certified.

Fully threaded rods manufactured to the F1554 anchor bolt specification require color coding as opposed to a permanent grade stamp. At Portland Bolt, we keep a large supply of full-length all thread rod on hand so that no matter what your job requires we are prepared to cut, chamfer, and stamp the rod to meet your job’s demands.

All thread rod is typically cut to length on a bandsaw. This leaves a flat surface on which to apply a chamfer and stamp the rod with the appropriate grade symbol and manufacturer’s identifier.

Many jobs require the rods to be hot-dip galvanized or otherwise coated. The customer and the supplier must address the issue of how to coat the cut ends. The two common options for hot dip galvanized are as follows.

Cut to Length from Galvanized

If the job allows it, the rods can be cut to length from a ten or twelve-foot stock length of hot-dip galvanized all thread. This means that the sawed end of the finished bolt will be uncoated.

After the rod has been chamfered and stamped we will spray the cut end of the rod with a zinc-rich primer to cold-galvanize the uncoated tip. The upside of this method is that it gets around the need to galvanize the rods, reducing the manufacturing lead time and shortening the timeframe between the customer ordering and receiving their bolts.

When the ends are prayed, the zinc does not bond to the steel as it does during the hot-dip galvanizing process leaving the ends susceptible to premature corrosion. Bear in mind that cold galvanizing (or “spray galvanizing”) is not allowed on every job and you should always consult with the engineer of record before ordering rods utilizing the cold galvanizing method.

Cut to Length and Galvanized

If a job doesn’t allow cold galvanizing then often the supplier will cut the rods from a plain finish, uncoated rod and hot-dip galvanize them after they have been chamfered and stamped.

Here at Portland Bolt, we have the advantage of hot-dip galvanizing bolts right here in our facility. This saves the customer the cost and manufacturing delays caused by sending the bolts to a coater.

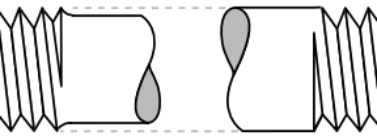

Additionally, our galvanizing line is designed expressly to coat threaded fasteners with a proprietary method for cleaning the threads. The bolts are spun at high speeds to remove excess zinc accrued during the dipping process.

This ensures that there is never any thread fit issue when assembling the nut.

What if a job requires a threaded rod that is not available in longer lengths?

When the size or grade of threaded rod a job requires is not already available off the shelf in a ten or twelve-foot length, Portland Bolt can always manufacture a rod that will meet all of the job’s requirements. We can apply threads to each end of a rod either by roll threading pitch diameter steel or cut threading full diameter round bar.

If you need all thread rod for your job, contact one of our experienced estimators and they will work you up a quote.

Can you tell me the difference between 1045 and B7 threaded rod

Rolled threads vs cut threads

Basically what I need to know is could you substitute B7 rolled threads for 1045 cut threads?

@Chris- 1045 steel is a medium carbon raw steel with no specific mechanical requirements whereas A193 B7 is a heat-treated alloy steel with very specific mechanical requirements and testing. They are not the same and any substitution would require the approval of the project engineer. The cut thread vs rolled thread would be less of a concern unless the project is specifically requiring one method.