How much coupling nut thread engagement is required to achieve the strength of the rod?

Unfortunately there appears to be no documented information on how much rod engagement into a coupling nut is required to achieve the strength of the rod or bolt being used with it. Coupling nuts are manufactured to the same ASTM specifications as regular hex nuts, and ASME B18.2.2 provides dimensional specifications for coupling nuts. Standard coupling nuts are 3 diameters in length. However, there is no reference to coupling nuts in the actual ASTM A563 or A194 nut specifications.

Unfortunately there appears to be no documented information on how much rod engagement into a coupling nut is required to achieve the strength of the rod or bolt being used with it. Coupling nuts are manufactured to the same ASTM specifications as regular hex nuts, and ASME B18.2.2 provides dimensional specifications for coupling nuts. Standard coupling nuts are 3 diameters in length. However, there is no reference to coupling nuts in the actual ASTM A563 or A194 nut specifications.

Your first step is making sure that the ASTM grade of coupling nut being used with the threaded rod or bolt is the same grade as the recommended grade of nut that would be used with the rod or bolt. For example, ASTM A193 B7 rods or bolts require an ASTM A194 2H heavy hex nut, so if you were to use a coupling nut with an ASTM A193 B7 rod, the grade of coupling nut should also be ASTM A194 2H. Although the amount of thread engagement is not specified, our coupling nut supplier recommends the bolt or rod should be threaded a minimum of one diameter in length into one end of the coupling nut.

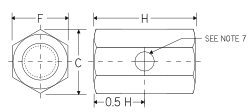

There may be an application which requires that the threaded parts going in each end of the coupling nut are engaged approximately one half of the coupling nut thickness. In this case, a hole may be drilled in the middle of one side of the coupling nut. This aids in the visual inspection to ensure that both rod ends are in fact meeting in the middle, not off center. According to IFI-128, note 7, the hole should be located at mid nut thickness and have a diameter of 0.2 to 0.4 times nominal nut size for sizes 2-1/2″ and smaller. For sizes 2-3/4″ and larger, the hole is 1″. Coupling nuts are manufactured without this hole unless otherwise specified.

As long as the correct grade of coupling nut is used and the bolts or rods are engaged a minimum of one diameter, the bolt should theoretically break before the threads strip. Again, this is only a common rule of thumb and we have no documented specifications that cover this issue. In any situation involving coupling nuts, we would recommend consulting with the engineer of record or a structural engineer to determine the appropriate length of coupling nut and amount of thread engagement required.

I need a 1 inch (25.4mmn) diameter coupling nut, not a specific length with a 1-20 Thread pitch. I ll need a specified amount, just need to know if those sizes are available

@Michael- We are not familiar with 1-20 threads, and would not be able to provide a coupler with those threads.

Hi,

A hanging bolt which has 2.5 MT load and required coupling nut as well to extent the length.how i can calculate the required minimum bolt size and coupling nut length?

@Lubna- Apologies, but we are unable to calculate those values for you. You will have to consult an engineer.

Is it possible for the coupling nuts to loosen off due to vibrations/elongation in the rod. Are there any specifications or vibration tests available that indicate if this is an issue with using coupling nuts. We are looking at using them for brace rods in crane buildings. We don’t want to specify tack welding as rods are galvanized. Also concerned with inducing fatigue cracks from the tack welding.

@Dennis- If vibration is a concern, and welding is not preferred, we are able to peen a thread, or that can be done in the field. By damaging a thread on one end or the other of the coupler, you are able to keep the coupler from backing off too far. You can also look at liquid thread lockers. We don’t have a lot of experience with those, but we know there are many types. As for a test or specification for vibration, we are not aware of anything.

I would like to use coupling nut to extend column anchor bolt. The coupling nut will be installed below column base plate ( existing anchor bolt dia. 1 3/8″). Is coupling nut the right application in this case?

After coupling nut and column base plate are installed, once it comes to tighten the nut with torque wrench, how could we control some relative motion/twist at the coupling nut?

@Nat- The coupler is a common fix for this problem, but we are unable to make any outright recommendations for your specific application. As for how to keep the coupler from rotating, you could try a tack weld if the situation allows.

Can I use coupler nuts to extend a 56mm diameter anchor bolt (8 nos) for a 20m high structure? The bolts were wrongly installed at 150mm above concrete and we need at least 500mm above concrete. Zinc plated A193 grade B7 bolts were installed.

@Isaac- Using a coupler to extend a base is a common method, however you will need to check with your project engineer to determine if it is the best method for your application.

I have a 3/8 threaded rod and trying to use a coupler to extend the rod. Is a 1/1/8″ Coupler sufficient for the attachment? Also does the length of a coupler increase the strength? or is the grade of material?

@Joseph- Couplers lengths are typically three times the diameter, so a 3/8″ diameter coupler should be 1-1/8″ long, and that is sufficient for general purpose applications. If your application requires something stronger, a higher grade is typically supplied. Increasing a coupler’s length does not increase it’s capacity.

Dane:

I need to extend 4 – 1″ dia. Galv. anchor bolts with standard threads and would like to use fabricated stand-off, in order to keep the length of the coupler to a minimum. The total length of the stand-off, including the coupler and threaded rod to be 6 1/2″ long. Can you weld a 1″ dia. galvanized threaded rod (ASTM A307) to a 2″ long galvanized coupler, leaving sufficient thread in the un-welded end of the coupler to meet the 1.5 x rod diameter requirement?

@Charlie- If I understand this correctly, that would leave the extension threaded only 1/2″ in and then welded? If your project engineer has evaluated this scenario and is confident that it will still support the load that it needs to support, I guess it would be acceptable. The rule of thumb is that you want the threads engaged at least one diameter, but that is simply a guideline and not an absolute law. If you feel that your solution will be the best fit for your project, and the project engineer signs off on it, then you should be ok.

I have an application where I would like to tack weld one-inch diameter threaded rods to coupler nuts. I understand that I can obtain weldable ASTM F1554 grade 55 threaded rod, but I would like also to obtain weldable couplers. Are weldable couplers available? if not, is there another option to welding that I’m not thinking of? Are sufficient chemical properties available for the coupler nuts so that I can calculate the Carbon Equivalent of your 1″ coupler nuts?

Thank you,

Chris

530-604-8090

@Chris- In the sampling of MTRs for some commonly available imported couplers, I found they were all made of low carbon steel like AISI 1010 and appeared to be weldable. We can’t say that ALL couplers are available, as other suppliers may have other sources, but we are comfortable saying that we could supply weldable couplers. Whomever they are sourced from, ask if they can supply MTRs showing the chemistry. If they can, it should be easy to determine if they are in fact weldable. Plan B would be to have couplers manufactured. That would also guarantee that they are weldable, but would be at a higher cost.

How difficult (more expensive) would it be to manufacture “positive engagement” coupler nuts in the 1/2′ to 3/4″ size so that it eliminates the potential for faulty installation that is more likely to happen at that location than anywhere else.

This webpage has an example of a positive engagement coupler.

https://www.hurribolt.com/compare.htm

@Clark- We would be able to quote your couplers as a special, so the cost would depend on the specifics (size, grade, quantity, finish) of what you are needing.

I’m looking for installation/inspection standards for the these coupling nuts. We plan to use these nuts to hang racks from inserts in a concrete deck. Is their a product spec or manufacturer installation recommendation that indicates whether or not the two rods should be visible touching or if it is acceptable can be an air gap between the two rods. If it is acceptable to have an air gap please specify the maximum that the air gap can be?

@Carson- We do not know of any published document regarding this. However, rule of thumb is that you want at least one diameter’s worth of thread engagement each end. Coupling nuts are usually three diameters long, for example a 1″ coupler is 3″ long. So if each end is engaged one diameter, that leaves one diameter of ‘gap’ in the middle. As long as the gap is not more than one diameter, you should be safe.

Can a coupling nut be used in SAG ROD applications? They want to tie into the tail-end of a sag rod above using a coupling nut, the extreme strength grade. Will the nut tend to wiggle loose over a period of time? Thank for the article!

@Perry- Yes, it may be acceptable to use a coupler in a sag rod application. However, the project engineer should be consulted to make sure there are not any special circumstances that may come into play.

Thank you for this great article!

I fully understand the concept behind the thread engagement lengths on couplers.

What I am interested in is the tensile load-deformation behaviour of couplers. In most cases, they are used for tension relevant applications. Are there test standards that qualify the axial ductility of the couplers and how compatible they are to the corresponding threaded rods that are screwed in to them? In other words, are they rated for specific ultimate tensile strengths and yield strengths in the same as bolts and threaded rods?

Thank you in advance.

@Ramil- As far as we know, that are not any standards that specifically cover coupling nuts. We typically have our couplers made to the same chemical and mechanical requirements as regular nuts. So from that standpoint, they are tested to the same loads as a regular nut of the same grade, but there aren’t any coupling nut load ratings.

We have a bulkhead project that requires 27′ long galv 1 1/4 tie backs with 12″ threaded ends ,hillside washers on both ends and heavy hex nuts , need a quanity of 21 please quote need delivery by 5 /20 at latest , let me know if interested

@Rich- One of our salespeople will contact you shortly.

I need six pieces of 1/2 inch threaded pod couplers. They should be 4″ long. Can you let me know what the cost would be and soon I can have them. Thank you Please reply

@Stuart – I’d need a bit more information about what a ‘pod’ coupler is. We do not stock any 1/2″ standard couplers that long, but could specially manufacture them. If you’d like to contact our sales department with more information, we’d be happy to look into it.

What is the largest coupler aviaible length

@Stuart – The largest we stock in our facility is 1-8 x 3. However, larger sizes can be easily brought in or made to order.

Hey Anthony,

Thanks for the awesome article. This explains everything I was curious about regarding coupling nut length.

I have a quick question for you:

Is it possible to couple A449 galvanized rod to plain steel rod? If so, do you need a customized A563 coupling nut?

For a continuous hold-down shear wall, I’d like to use galvanized rod only for the segment embedded in a concrete footing, then couple it to plain steel rod above the mud sill. The plain steel segment would then extend upward about 7 feet into the shear wall.

However, since the galvanized rod has a slightly larger diameter because of the coating, I’m curious if there is a coupling nut that is half oversized for galvanized rod and half standard for plain steel rod?

Thanks,

Mike

415-696-6323

@Mike – Yes, it is possible to get a coupler like that. It would be a special, but it shouldn’t be too hard to make. We’d simply galvanize the whole thing, and tap out one end oversize for the galvanized rod, and tap out the other end standard, for the plain end rod. We done similar things before. If you want to let us know the details, we’d be happy to quote it. We can supply the A449 all thread as well.

Regarding hot dip galvanized threaded rod, nuts, and couplings. It appears to me that the rod and percentage of thread are slightly reduced to accommodate a 0.0017 coating,,,,, or not? If not, the hot-dipped nuts are bored and threaded slightly larger, to accommodate that 0.0017 zinc coating.

So, particularly if any reduction is made to the rod or bolt, some reduction of strength would occur, BUT, even if the male threaded steel piece is not reduced, the thread engagement will reduce if the female thread has an allowance for 0.0017 OR 0.0034 (.0017×2) of zinc, AND (obviously) the strength of zinc is substantially lower than steel,,,,, so, the pullout strength must be substantially lower for an assembly of hot-dipped components. I’m curious, but I’d guess that percentage of thread on typical “all thread” is relatively low,,, and as you might guess, I’m questioning the capacity of some of my installed and planned assemblies.

Any thoughts of info?

@Gary- You are correct that the capacity of galvanized, overtapped nuts is slightly less that their plain finish counterparts. However, the amount that they are tapped oversize does not reduce their tensile capacity below that of the mating rod, so the ultimate tensile strength of the assembly is not compromised. The root of the thread of the rod is still the weakest part of the assembly.