Steel Fabrication (New)

Tough Specs, Tight Deadlines? We Don’t Think So.

Portland Bolt is a trusted manufacturing partner to steel fabricators across North America. As a leading supplier of standard and custom bolts and fasteners, we specialize in anchor bolts, tie-rod assemblies, and other project-specific bolts that meet the complex demands of modern steel construction. Our vertically integrated operation includes hot-forging, threading, galvanizing, and testing, all under one roof. This structure gives us full control over quality and lead times, from raw steel to finished product.

Commonly Used Products

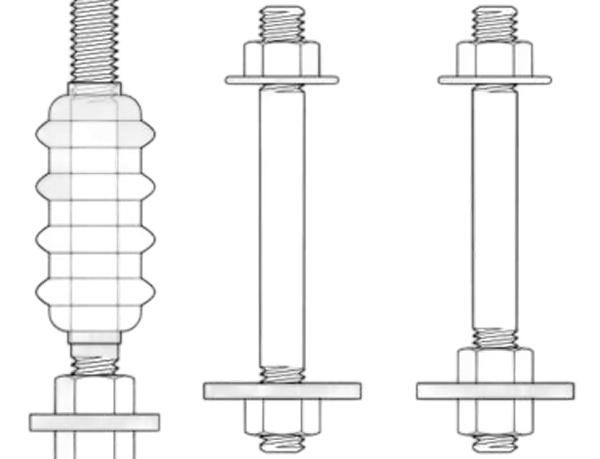

Hex Bolt Assemblies »

Hex bolts are a staple fastener for structural assemblies. Portland Bolt manufactures hex head bolts up to 2-1/2″ diameter, in multiple ASTM grades, made from domestic steel. Commonly commonly used as anchor bolts with the headed end embedded in the concrete.

Structural Bolts »

Our heavy hex structural bolts meet ASTM F3125 Grades A325 and A490 specifications and are available from 1/2″ to 1-1/2″ diameter. These bolts are engineered for high-strength structural joints in steel buildings and bridges, where load transfer and shear resistance are critical.

Anchor Rods »

We manufacture anchor rods in straight and bent configurations, in a wide variety of materials including F1554 grade 36, 55, and 105. These rods serve as the interface between structural steel and concrete foundations, customized for embedment depth, threading requirements, and finish.

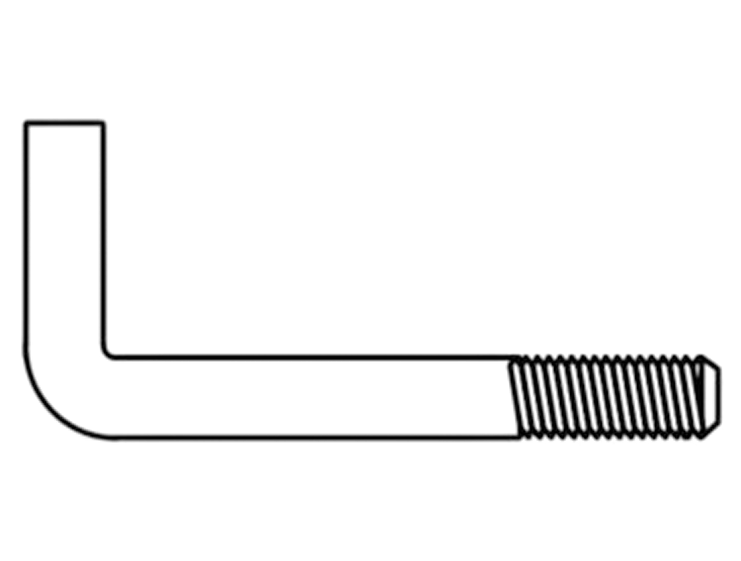

90° Anchor Bolts »

Our 90-degree bend anchor bolts are among the most widely used solutions for embedded concrete-to-steel connections. These bolts are made to order with the required thread length, hook dimensions, and finishes such as plain or galvanized. In addition to making custom, we stock a complete line from .5″ diameter through 1.25″ diameter up to 42″ in length.

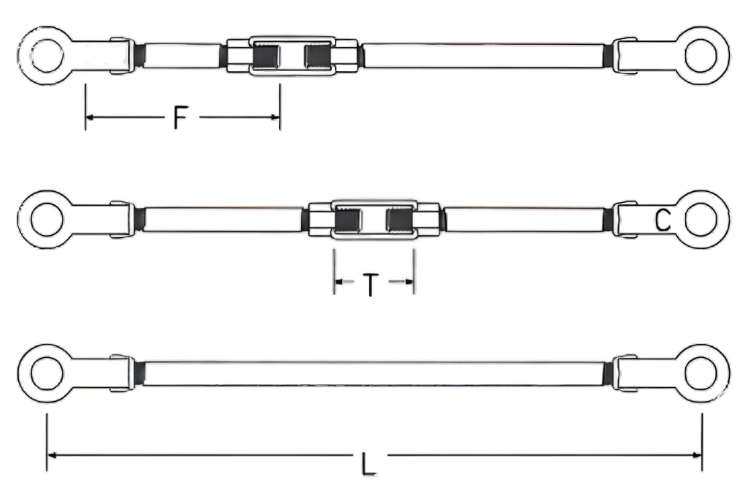

Tie Rods »

Tie rod assemblies are used to brace structural steel components, particularly in long-span or open-web truss designs. Portland Bolt fabricates fully assembled systems with clevises, turnbuckles, and rods, ensuring strength and adjustability in structural bracing.

Plates »

Our plasma cuts plate material up to 1.5″ thick, providing a precise and efficient solution for producing base plates, splice plates, and washer plates. We also fabricate complex angle assemblies with multiple holes, ideal for structural gussets and steel framing connections.

Why Steel Fabricators Trust Portland Bolt

Speed Without Compromise

Our domestic material inventory includes 12 steel grades across 23 diameters (from 1/2″ to 3-1/2″), allowing us to manufacture to spec with minimal delay. In-house galvanizing and testing eliminate outsourcing delays.

Expertise in Custom Fabrication

Every steel fabrication project is different. Our experienced team produces fasteners to suit your project’s drawings, load requirements, and environmental considerations.

Quality & Scheduling You Can Rely On

Our production line is dedicated exclusively to threaded fasteners, ensuring a precise, trouble-free nut fit. By controlling our own scheduling, we’re able to deliver consistent quality with fast turnaround times to keep your projects moving.

Precision & Performance

Our manufacturing tolerances are maintained through rigorous quality control, ensuring all bolts meet specification and fit perfectly during steel erection.

Full Traceability

All products are fully traceable with domestic melt and manufacture. Certification packages are delivered automatically and stored indefinitely for your records.

Stocked & Ready to Ship

In addition to custom-manufactured products, Portland Bolt stocks a complete line of standard structural bolts ready for immediate shipment. This ensures fabricators can rely on us not only for specialty fasteners built to exact specifications, but also for quick access to the standard sizes needed to keep projects on schedule.

Proper Bolt Torque:

Why It Matters & How to Do It Right

The fundamentals and one simple technique most overlook. Getting torque right takes more than charts and formulas. This quick guide covers the essentials for achieving consistent tension in real-world conditions – from surface prep and lubrication to tightening sequence and verification. A must-read for anyone who wants confidence that every bolt is performing as intended.

Frequently Asked Questions

Steel is produced by rolling mills to specifications that cover steel shapes, plates, and bars. Portland Bolt uses steel round bar to manufacture bolts to specifications that cover threaded fasteners.

General steel specifications, such as ASTM A36 and A572 or AISI 1045 and 4140 are manufactured to specific chemical and (sometimes) mechanical requirements. Heat analysis is used to determine the chemical composition while the mechanical properties are evaluated by tension testing.

Portland Bolt purchases steel round bar from rolling mills to specific chemistry and mechanical values in order to manufacture threaded fasteners. A heat number and lot number is recorded and provided by the steel mill along with mill test reports to ensure the steel is traceable and meets the requirements of the order.

A certain strength and chemistry of steel round bar will be selected depending on the specification and grade of fastener that Portland Bolt is manufacturing. Once production of the fastener is complete, a certification document will be compiled which includes the mill test reports of the steel in order to prove the fastener meets the necessary requirements. For example, when low carbon steel round bar is converted into a fastener by cutting, threading, bending, and/or heading, it is now certified under a fastener specification such as F1554 Grade 36 instead of the steel specification A36.

Specifications for threaded fasteners are different than steel specifications because the bolt specs have to cover details such as suitable nuts, thread geometry, bolt dimensions, test methods, product marking, and supplementary requirements.

The short answer is that in most cases, welding high strength bolts is not allowed. In the fastener industry, the term “high strength” typically refers to any medium carbon or alloy steel which undergoes a heat-treating process to develop the strength properties necessary to meet the requirements of a given specification. These ASTM specifications include A449, A325, A193 Grade B7, A320 Grade L7, F1554 Grade 105, A354 Grades BC and BD, and A490 among others.

When heat is reapplied to a bolt that has been heat-treated, it is likely that the physical properties (strength) of the bolt may be altered. When heat is applied in an uncontrolled environment, it is impossible to determine what effect this application of heat has had on the fastener. Therefore, welding to high strength bolts is not recommended.

Three references occur to back up this statement. Continue Reading

When a threaded rod with a nut is substituted for a bolt with a forged head, two issues come into play. When in-house mechanical testing was performed by Portland Bolt on headed bolts versus rods with a nut, both from the identical lots of steel, the rod with a nut developed up to 12% less strength than the comparable headed bolt.

The reason for this reduction in strength on the rod with nut is that the stress area at the junction of the rod and nut (which is substituting for the forged bolt head) is significantly reduced. Because the minor diameter (root) of the threads is significantly less than the full-size diameter of the unthreaded shank on a headed bolt, the rod with nut often breaks at a much lower strength than a headed bolt.

More importantly, even if the rod with nut does develop enough strength to meet the specification, it will often break at the junction of the nut which is acting as the head of the bolt when wedge tested per ASTM F606. For this reason, technically a rod with a nut in lieu of a headed bolt will frequently fail mechanical testing because the head (nut in this case) comes off before the bolt breaks in the body or threaded section of the fastener which constitutes an automatic failure.

Engineers occasionally specify the use of F3125 Grade A325 heavy hex structural bolts as anchor bolts, but technically they are supposed to be used for structural steel connections only. Part of the problem is that the A325 specification is very specific as to the application and thread length.

Because A325 bolts are typically used in structural steel connections, they have very short thread lengths. Often this thread length restriction is too short when the bolts are used as anchor bolts. Since the A325 specification was recategorized under the F3125 specification in 2016, extending the thread length is now allowed provided the heads are marked “A325S” to indicate a nonstandard thread length. Most A325 bolts used as anchor bolts will possess an extended thread length and be marked accordingly.

We occasionally see inquiries for A325 bent anchor bolts or straight anchor rods with anchor plates. Since the A325 specification is restricted to headed bolts only, the F3125 Grade A325 specification suggests moving to either ASTM A449 or A354 Grade BC in these instances. Since both A449 and A354 specifications are designed for general applications (including anchor bolts), engineers should consider these specifications for headed anchor bolts in lieu of F3125 Grade A325 when a similar strength and chemistry is desired. The F1554 specification was developed specifically for anchor bolts and may also be a more appropriate specification to consider when specifying anchor bolts. AISC also discusses which ASTM specifications should be used as anchor bolts.

The short answer is that F3125 Grade A490 heavy hex structural bolts have higher strength requirements than A325 heavy hex structural bolts. A325 bolts have a minimum tensile strength of 120ksi while A490 bolts have a tensile strength range of 150-173ksi.

In addition, there are a few other differences shown here.

There are no standard thread length calculations for anchor rods. Anchor bolt thread length will depend on the required projection for the protruding end and the required hardware or configuration for the embedded end. It is very common for structural drawings to detail the required thread lengths for anchor bolts.

Bottom Threads

Bottom threads will not be required if the anchor is a 90° bent, swedged, or headed configuration. If the anchor has bottom threads, the length will usually be determined by the thickness of material that is being assembled onto the threads plus a small amount of additional thread for welding, peening (damaging threads), or adjustment purposes.

Top Threads

Top threads on anchor rods are longer than the bottom threads in normal circumstances. The thread length at the top of the anchor will almost always be determined by the projection from the top of concrete. It is normal for about 1″ to be added to the projection to equal the top thread length. The added length can helpful in providing a slight adjustment to aid with installation.

When the projection is unknown, the thread length will be calculated by adding the thickness of the nut(s), jamb nut (when applicable), washer(s), and the thickness of the base plate of the structure being bolted to the foundation. Typically, an inch or two is added to the sum of these components to determine the projection and subsequent top thread length.

To assist inspectors and installation crews in the field, the threaded end of all F1554 anchor bolts intended to project from the concrete should be color coded or permanently marked with the grade symbol and/or manufacturer’s identifier.

In most situations, the thread lengths for anchor rods will be determined by the engineer and detailed on the construction plans. If the anchor rod thread lengths are not provided, using the information listed above should help in determining the required top and bottom thread lengths. Continue Reading

PROJECT AT A GLANCE

Rhythm City Skybridge

OWNER/ BUDGET: Province of British Columbia · US $1.38 B

SCOPE: New 4-lane Fraser River crossing with protected bike & pedestrian lanes, future light-rail allowance, and integrated snow/ice removal system

Portland Bolt secured a contract to manufacture 85,000 pounds of 4″ and 4-1/2″ diameter A572 grade 50 structural hanger rods measuring up to 68′ in length for the Rhythm City Skybridge.

As part of Davenport, Iowa’s downtown redevelopment, the Rhythm City Skybridge connects a plaza in the 100 block of West 2nd Street with the front of the Rhythm City Riverboat Casino.