Steven's FAQs

Stainless steel fasteners are often used in highly corrosive environments. When stainless nuts begin to rust, this can occur when hot forged nuts that are manufactured only to a material grade such as 18-8, SS304, and SS316 or to the ASTM A194 Grade 8 or 8M specifications. None of these steel grades or nut specifications... Read more

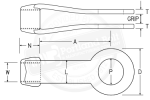

A clevis is a forged component at the end of a tie rod assembly that secures one end of a threaded rod to a structure. The “grip” of a clevis is the distance between the ears and is typically ¼” wider than the thickness of the connecting plate. This dimension is important so that the... Read more

No, only Type 316 stainless steel clevis forgings are available off the shelf. Suppliers choose not to double inventory them since 316 stainless is virtually identical in strength to 304 stainless and provides more corrosion resistance. Type 304 stainless threaded rods are frequently supplied with Type 316 stainless clevises. If a 304 stainless clevis is... Read more

No, only Type 316 stainless steel clevis forging are available off the shelf. Suppliers choose not to double inventory them since 316 stainless is virtually identical in strength to 304 stainless and provides more corrosion resistance. Type 304 stainless threaded rods are frequently supplied with Type 316 stainless clevises. If a 304 stainless clevis is... Read more

DFARS stands for Defense Federal Acquisition Regulation Supplement. This is a set of rules and restrictions that makes domestic or NATO materials preferred for United States defense contractors on military projects. A clause was added in 1973, amending the original regulation, currently allowing for materials to be melted in the following qualified countries per DFARS... Read more

RCSC is the Research Council on Structural Connections. It is a non-profit, volunteer organization, comprised of over 85 leading experts in the fields of structural steel connection design, engineering, fabrication, erection and bolting. Its goal is to support research and gain knowledge to publish standards in structural steel connections.

Looking through both the ASTM specification F3125 Grade A325 and the Research Council on Structural Connections (RCSC) website, we have found neither mentioning the use of lock washers in a structural steel connection. We interpret this as neither allowing nor forbidding the use and that it would ultimately be up to the engineer of record... Read more

There are two possible causes for this. First is that oxidation can occur due to contamination from equipment that is used to make other carbon steel products. This can leave some iron deposits that will rust over time. This is only aesthetic, but can be unsightly. The second possibility is that the bolts were not... Read more

The easiest way to lock a tie rod assembly in place is by including an extra nut that can be run up against either the clevis or the turnbuckle. Once the nut has been jammed in place the assembly will be unable to move. These pictures show that the nut has to be placed on... Read more

High-strength clevises can be provided in instances where smaller clevises are needed while keeping a higher safe working load. High-strength clevises are also used to develop the full capacity of high-strength threaded rods. Since high-strength clevises are not readily available in the marketplace, these items can add significant lead time and cost to the assembly.... Read more