How large should I oversize my plate holes?

Square plates, rectangular plates, round plates, and templates are often required as part of an anchor bolt or fastener assembly. These plates serve as either large, oversized washers or anchor plates which are fastened to the bottom of anchor rods to provide pull-out resistance. Plates and washers are typically manufactured to ASTM A36, A572 grade 50, or ASTM F436, although other options exist. The amount that a hole in a plate is oversized (larger than the bolt diameter) will often depend on the thickness of the plate, the application of the plate, and the equipment used to fabricate the plate.

Square plates, rectangular plates, round plates, and templates are often required as part of an anchor bolt or fastener assembly. These plates serve as either large, oversized washers or anchor plates which are fastened to the bottom of anchor rods to provide pull-out resistance. Plates and washers are typically manufactured to ASTM A36, A572 grade 50, or ASTM F436, although other options exist. The amount that a hole in a plate is oversized (larger than the bolt diameter) will often depend on the thickness of the plate, the application of the plate, and the equipment used to fabricate the plate.

Portland Bolt will always provide plates to the dimensions requested by the customer, including the size of the hole. However, often times the hole size has not been detailed and is left up to the customer to determine. Portland Bolt has some standard guidelines that we have developed depending on the application of the plate to appropriately oversize the hole for ease of manufacturing and installation. We use a 150 ton Uni-Hydro Iron Worker to punch A36 plates up to 1” thick. Holes in thicker plates are either flame cut, laser cut, or cut using high definition plasma.

Basic Guidelines

Punched Holes:

Portland Bolt uses a 150 ton Uni-Hydro Iron Worker to hydraulically punch holes in plates.

- A36 flat bar / plate only

- Maximum 1” plate thickness

- No holes smaller than plate thickness

- The distance between the edge of the hole and the outside edge of the plate, should be greater than the thickness of the plate.

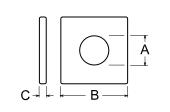

B > A + 2C

B > A + 2C

Note: For plates in which the measurement from the outer edge of the hole to the outer edge of the plate is less than the plate thickness or plates in which the hole is smaller than or equal to the plate thickness, holes will need to be drilled or laser cut rather than punched.

Laser Cut Holes

Lasers cut holes in plates by melting or burning the steel in the beam’s path. Lasers are precise and leave the plates with a high quality surface finish.

- Mild steel only

- Maximum 1″ plate thickness

- Tolerances of +/- .005”

- Holes can be smaller than the plate thickness

High Definition Plasma Cut Holes

A simplified explanation of how plasma cutters work is that they send an electric arc through a gas that is passing through a constricted opening. The stream of ionized gas cuts the steel.

- Carbon and stainless steel

- 3/8″ – 1-1/4″ plate thickness

- Tolerances of +/- 1-16”

- No holes smaller than the plate thickness

- Can produce a slightly tapered hole

Flame Cut Holes

Flame cutting uses oxygen and a fuel gas to preheat the steel. A jet of oxygen is then directed into the steel, piercing through the plate.

- Carbon and alloy steels

- 1-1/4″ and larger plate thicknesses

- Tolerances of +/- 1/16”

- No holes smaller than plate thickness

Plate Hole Oversizing Guidelines

Plates Assembled On Rods

- Punched / Laser Cut Hole for plate thickness < 1″: 1/16″ oversize

- Punched / Laser Cut Hole for plate thickness of 1″: 1/8″ oversize

- Plasma / Flame Cut Hole: 1/4″ oversize

Plates Welded to a Nut

- Punched / Laser / Plasma / Flame Cut Hole: 1/4″ oversize

Plates Welded Directly to Rod

- Drilled / Punched / Laser Cut Holes: 1/16″ oversize

Please note, these guidelines are used by Portland Bolt when plate hole sizes have not been specified by an engineer, and may not be appropriate for all applications. We would recommend clearing these hole sizes with an engineer prior to ordering since different applications may require different hole sizes in plates.

Need price on 200 bearing plates hdg 3″x3″ 3/4″ hole. delivered to AML Seattle Washington 98106

@Robert – one of our salespeople will contact you shortly.

HOW TO USE THE BOLT OF M33 IN AN HOLE OF 38 MM DIAMETER ?

IS THERE ANY SUPPORTING AISC / ASME CODE FOR USE OF BUSH IN THE HOLE .

@Sandeep- For structural grades like A325 and A490, you can use the chart in this table to determine what washer to use for oversized holes. For other grades and the use of bushings, we unfortunately do not have any information.

Can you provide square washers with a slotted hole? I am looking for 1200 EA 4″X4″X1/2 washers with a 5/8″X1-3/4″ slotted hole. HDG.

@Tom- Thank you for the inquiry, one of our salespeople will contact you shortly.

Dear Sirs,

What would the cost be for a galvanized washer , 3″x3″x1/4″ thick with an 1-3/8″ hole.

@Robert- One of our salespeople will contact you shortly to get the specifics of your inquiry.

Is F436 washer material weldable?

@Alan – No, F436 washers get their strength from a heat treating process, so the addition of heat during welding would detrimentally affect the strength of the washers.