I need to buy some non-standard size u-bolts. Do you have any guidelines that will help me with ordering the u-bolts I need from Portland Bolt?

Portland Bolt can manufacture custom u-bolts that are made from 1/2” diameter and larger steel. So as long as the u-bolts you need are 1/2” in diameter or larger, we can most likely manufacture them, within the capabilities of our bending equipment and the limitations of the steel itself. To better understand what can be manufactured you will need to know a little about the way that we manufacture u-bolts.

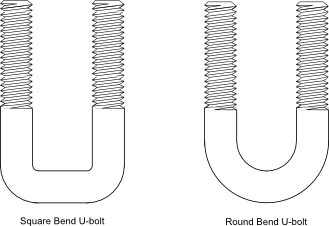

Round Bend U-Bolts

There are two types of u-bolts, round bend u-bolts and square bend u-bolts. Round bend u-bolts are shaped like the letter “U” and are typically used to attach something to a round pole or a pipe. To manufacture a round bend u-bolt, we first cut a section of steel round bar to the appropriate length and then bend that piece of steel around a pin that has the same diameter as what is desired in the final u-bolt. For example, if you need a round bend u-bolt that will fit around a 3” diameter pole, we would bend it around a 3” diameter pin. You can see a brief video of this operation below:

Square Bend U-Bolts

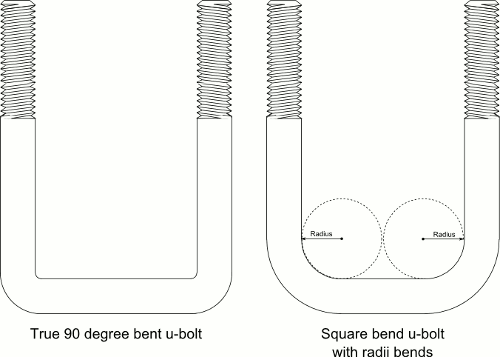

The other type of u-bolt is a square bend u-bolt. Applications can vary, but this style of u-bolt is usually going around something generally square or rectangular in shape, such as a square wooden beam or square steel tubing. Fabricating this style of u-bolt is more complicated and requires some additional considerations. Before we can begin manufacturing this style of u-bolt we will need to know some additional information. Because the u-bolt will be manufactured from steel bars that are round in shape, and will be bent around a round pin, the bends themselves will have a rounded profile. In many construction applications this is not a problem. In some precision applications, however, such as in some automotive or trailer uses, the u-bolt may be required to have a true, sharp, right angle inside the bend. In cases like these, we would most likely not be able to manufacture the u-bolt required.

Determining A Bend Radius

Once you have determined that bends with a radius will be acceptable for your application, the next thing that must be considered is the relationship between the diameter of the u-bolt and the radius of the bend. For a square bend u-bolt the general rule of thumb is that the radius of the bend must be at least twice the diameter of the material being bent. For example, in the case of a square bend u-bolt being made from 1/2” material, the radius of each bend must be at least 1”. In some cases, sharper bends can be performed through a hot bending operation which involves additional labor.

Other Considerations

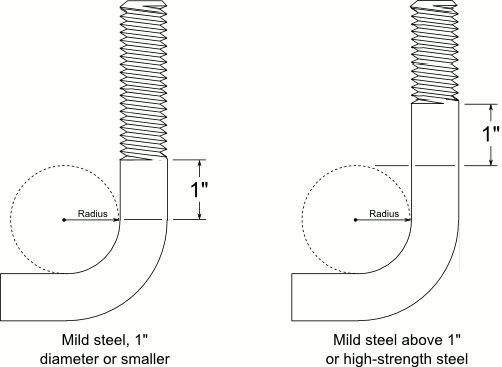

Another aspect of u-bolt manufacturing that must be considered is the amount of thread on each leg in relation to the length of those legs. The thread length will be a function of the diameter of the material, the type of steel being used (mild steel or high strength), and the radius of the bend. Generally speaking, u-bolts fall into two categories here:

- U-bolts made from mild steel that is 1″ diameter or smaller, OR

- U-bolts made from either mild steel 1-1/8″ diameter and above, or made from high strength steel of any diameter.

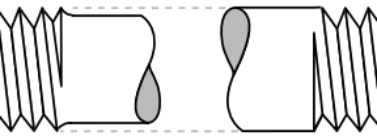

In the case of group 1 the general rule is that the threads should not begin until you are at least one inch beyond the radius of the bend. In the case of group 2, the rule is that the threads should not begin until you are at least 1″ beyond the diameter (twice the radius) of the bend. The reason for these restrictions is because threads extending further down the leg of the u-bolt will encroach into the area of the steel being bent during fabrication, and will subsequently be smashed flat by the bending rollers. Bear in mind that the 1″ distance beyond the radius or diameter is the minimum. More distance is always preferable.

A final item that may sometimes be a factor to consider is the ASTM specification to which the u-bolts you need are being manufactured. If your u-bolts are being manufactured from a quenched and tempered, high-strength steel there is a possibility that the material may have to be heated before bending to achieve the desired shape. In cases like this, the material will have to be sent to a metal heat treating company to undergo a heat treating process to restore the high strength properties in the portion of steel that was heated during fabrication. This will add additional time and cost to the production of your order.

We Can Help

Keep in mind that the information in this FAQ is intended to serve as a guide to help you better understand the types of u-bolts that we can best help you out with. As with any guidelines, there will always be special cases and exceptions to the rules. If you are uncertain about whether Portland Bolt can help you out with your u-bolt requirements, please contact one of our experienced sales team members and we will be glad to help walk you through it!

I am building a BBQ, and I need a couple of U-shaped pieces of metal that are made of 5/8 rod and have an inside bend of 3 inches (diameter). The legs need to be at least 10 inches long.

Since this will not be used as U-bolts, but rather handles, can I buy them unthreaded from you? Thank you.

@James- We sell primarily to commercial users, and so are probably not the best source for only a couple of these u-bolts. A local steel fab shop could probably bend them for you a lot easier (and cheaper).

I need a 1/2″ u- bolts

1 1/8″ ID

Bolt can be 6 or- 9′ long

Marine grade

How do I order?

Or do you have in stock?

@John- One of our salespeople will contact you regarding this.

Can you make 1/2″ x 15″ x 2 1/2″ x 5″?

How much each?

@John- Thank you for the inquiry, one of our salespeople will be contacting you shortly.

I am looking to use two square U-Bolts to secure a plate to 4″ square tubing. Would a 4″ inside dimension be too tight for this application or would it be recommended to have a custom U-Bolt fabricated to give some wiggle room for assembly?

@Mat- That would be up to you. There are tolerances for both the U-bolt and the tubing, so depending on where the two components fall in their tolerance range, it is possible that they fit tightly, but they could also fit loosely. In this case it would depend on what is more important to you; having some wiggle room, or the cost; as custom u-bolts will be more expensive.

I intend to manually bend some A325 Type 1 Threaded Both End Bars (6mm, 10mm & 1/2″ diameters), to form 180 degree Round Bend U Bolts..

Bend radius is not an issue as will exceed the minimums..

My questions are..

Does A325 Type 1 with those small diameters will need to be heated during bending process?

Does A325 Type 1 too brittle to bend?

The problem is I don’t have a heat treatment facility to do another heat treatment process after the bending, to restore the high strength properties..

(Threaded Both End Bars are ordered instead of U Bolts form due to flexibility reasons when applying at project site)

I hope you can help me.. Thank you

@Al- First of all, A325 does not cover small diameter threaded bar, so I would double check what you actually have. Our hunch is that it is not certified to A325, but perhaps something similar. That said, if what you have is similar in strength and chemistry to A325, then care should be used when bending. If heat is applied, then you are correct – you may adversely affect the steel and it may need to be re-heat treated in order to keep it’s strength. You may be able to cold bend it, but it will depend on the details. Many steels can be cold bent without cracking, but the bend radius and type of steel are the primary governing factors.

Thank you Dane, you helped a lot to better understand this..

M6 Dia Bar is for 0.5″ – 0.75″ Pipe diameters..

M10 Dia Bar is for 1″ – 2″ Pipe diameters..

1/2″ Dia Bar is for 3″ – 4″ Pipe diameters..

I am not sure if those bend radiuses will be sufficient for me to do a cold bending without cracking the bars?

I suppose the specification is A449 or something similar..

Since many manufacturers offer to provide A325 Bolts in custom forms..

On the contrary with what I have learned here..

Another problem occured since I have to apply a Cover / Polyshrink sheath.. so a re-heat treatment after bending will be a problem since the cover will melt away..

After several trials I found it very difficult to apply the cover after the Round U Bolts are formed.. wrinkles occured along the inner side of the Round U Bolts..

Is there anyway to solve that?

Probably a specific trick or method?

Or a specific type of Poly shrink cover?

This is to prevent corrosion from CS – SS surface contact..

Thank you

@Al- Our rule of thumb for cold bending this type of material is that the bending pin is 4x the diameter of the steel, so for 1/2″ would be 2″. I don’t have any information or recommendations on the cover – we don’t have any experience with that.

Thank you Dane, I will try to perform the bending test.. And will do a mechanical test at the lab on the finished products..

Thank you again..

I am looking for 1″ Id x 3″ L square bend U bolts. I need them to fasten boards to 1×2 rectangle tubing, does anyone make them?

Thanks

@Kelly- Those are too small for us to manufacture. I would try some local fastener distributors to see if those are available.

Is there a minimum order ?

@Jairus- We are a custom manufacturer, so our minimums reflect the costs necessary to manufacture your bolt. If you’d like to contact us and let us know what it is that you need, we can give you a better idea what a cost would be.

Dear Mr Derek,

Greetings ,

I was wondering about the problem of calculating the bar length for a semi round and round U bolt of rod dia 20mm and 22mm. Can you please help me out for this problem

Thanks and regards

@Debashish – Thank you for your question. We would need to see a drawing for your u-bolts in order to do any calculations. We can manufacture imperial dimensioned u-bolts and would be happy to quote your requirements.

Hi Derek,

I wonder if we can get U-bolt with SA325? and if yes, what is the differnce between SA325 and SA307?

Thanks

Mohamed

Dear Mr. Derek Marquez.

I have one question,

I received drawing for manufactur anchor bolt.

Type : Round bend U bolt

Diameter : 1 1/4 inch

Material : A 36 or SS 400

Process : Cold bending process

It’s could be manufactured without crack?

Thank you very much for your advise.

@ThomasTurnagger – We can cold bend stainless without cracking, but it would depend on the bend radius required. If you’d like to send in a drawing, we’d be happy to take a look at it.