What is a “CMTR”?

The acronym CMTR stands for, “Certified Mill Test Report” or “Certified Material Test Reports.” As a manufacturer, it is imperative that we are using the correct raw material when manufacturing a given part, whether it is a bolt or fabricated steel plate. A CMTR is provided by the raw material producer (mill), which is a document assuring quality and providing evidence of the chemistry and mechanical properties of the steel. CMTRs may have other call outs, such as a Mill Test Report (MTR) or Metallurgical Test Report. Regardless of how this document is titled, it has the same purpose, which is to document the testing results for a particular heat of steel and to provide traceability to the material’s origins.

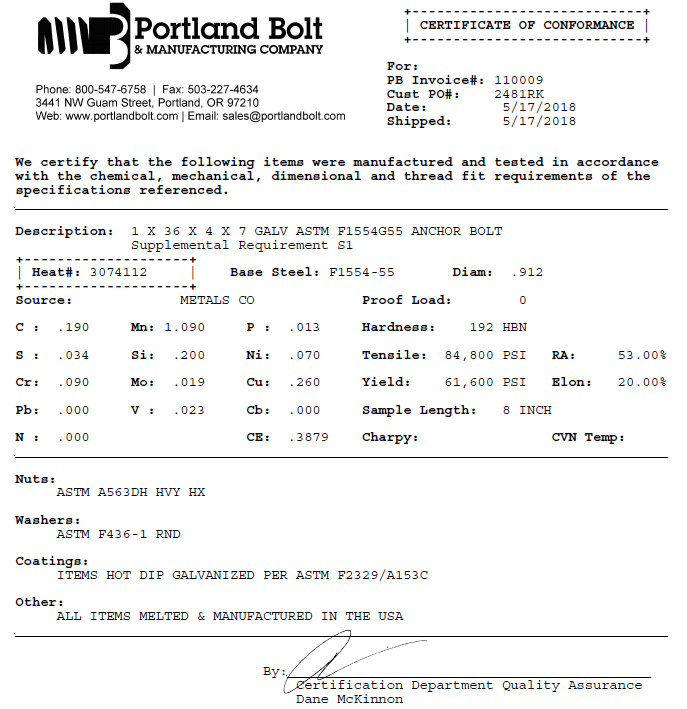

Within the CMTR, there are critical pieces of information, which must always be included:

Material Heat Number

Each rolling of round bar has its own mechanical and chemical attributes. To keep track of this, a heat number is assigned to each rolling. This allows for a manufacturer, such as Portland Bolt, to keep each heat lot separate so that we know exactly what round bar is associated with a given batch of fasteners produced.

Material Grade

When raw material is ordered, a material grade is specified. Not all grades are created equal and some grades may have strength requirements that are less than or greater than the strength requirements of another grade. The CMTR must clearly document which grade specification they meet so that the manufacturer can verify that the mechanical and chemical data meets the requirements of the given specification.

Material Dimensions

This is simply a way of knowing what diameter and lengths of material have been produced and delivered.

Mechanical Properties

The minimum strength requirement of a specified grade of steel is given in pounds per square inch (psi) or thousands of pounds per square inch (ksi). These are referred to as the mechanical requirements and are expressed in yield and in tensile as well as elongation % minimum and reduction of area % minimum. It is critical that these values are stated within the CMTR to provide evidence that the round bar supplied meets the strength requirements of the round bar ordered. Different grades of steel round bar require different testing to determine various strength characteristics. Sometimes, additional testing on finished fasteners is required, and those values supplement the original Certified Mill Test Report.

Chemical Requirements

The chemical requirements for a given grade of steel are specified in the ASTM steel standards. They are a way of evaluating and classifying a given grade since there are a wide variety of metallurgical properties in the different types of steels. Steel can be of the carbon, structural, stainless, ferritic, austenitic, and alloy types. These steel standards are helpful in guiding metallurgical laboratories and product manufacturers in their proper processing and application procedures to ensure that the appropriate steel is being used.

Heat Treatment

Some grades of steel require a heat treating process to achieve the strength requirements required by the ASTM standard. The CMTR should clearly show the heat treating process used as well as the testing results, post heat treating.

As you can see, CMTRs are not to be overlooked. If a supplier does not regularly supply CMTRs with their finished product, it could put your project at risk, especially if you are asked to provide evidence that the fasteners used actually meet the grade required by the engineer. It is standard practice for Portland Bolt to supply CMTRs with all of the bolts that we produce at no additional cost, whether you request them or not. We feel that it is imperative that our customers have all of the pertinent documentation on hand in order to alleviate any potential project delays, confusion, or liability.

Thers is not Heat no. at stud bolt.

How can the Inspection Certificate be Traceable to the actual item ?

@Glowintec- You will have to contact your supplier to find out their material traceability procedures in order to assure that you have received the correct item.

Que tal Anthony Porreco buen dia .

Tengo una pregunta con respecto al ejemplo de CMTR que muestras, todo me queda claro en cuanto propiedades mecánicas como en requerimientos químicos sin embargo no especificas que acero se utilizo para la fabricación de la ancla de cimentación f1554 Gr 55, como tampoco se especifica si se realizo un tratamiento térmico.

ojala y puedas ayudarme en responder mi pregunta

@Jesus- Hay muchos grados que se pueden usar para F1554g55, tenemos nuestro acero laminado específicamente para cumplir con ese grado. El tratamiento térmico es un proceso opcional que depende de las necesidades y capacidades del fabricante, no es necesario si puede lograr las propiedades mecánicas deseadas sin él.