Marine (New)

Strength Forged for the Sea

Portland Bolt is a trusted manufacturing partner to marine construction contractors worldwide. For over a century, we’ve supplied the specialized fasteners and hardware required to build and maintain docks, marinas, piers, seawalls, and port facilities. Our in-house ability to hot-forge, thread, galvanize, and test fasteners means we control quality and lead time from raw steel through finished product.

We’ve supplied marine projects across U.S. coasts and internationally – China, Korea, Japan, and Pakistan – delivering marine fasteners built to spec and scale. With a massive steel inventory on hand, 2 million pounds of round bar and plate stock in our facilities nationwide, we begin production immediately. Plus, our expedited and rush order options help us meet tight schedules when time matters most. When schedules tighten and environments challenge, contractors rely on Portland Bolt.

Strength you can trust. Service you can count on.

Commonly Used Products

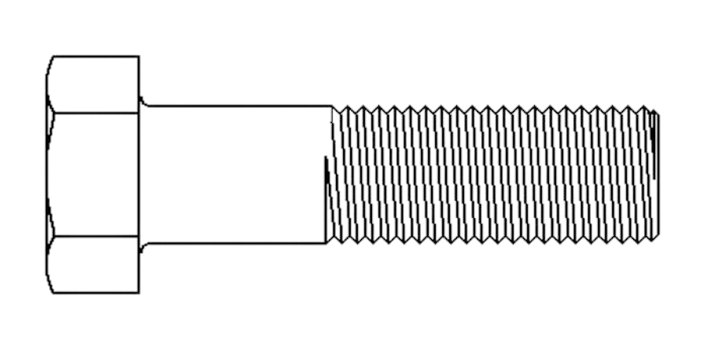

Hex Bolts »

Hex bolts are a staple fastener in marine construction, used to join heavy timber components, dock framing, and pier assemblies. Portland Bolt manufactures hex head bolts up to 2-1/2″ in diameter, in multiple ASTM grades, using domestic steel. Available with hot-dip galvanizing or stainless steel finishes, they deliver strength and corrosion protection in saltwater environments.

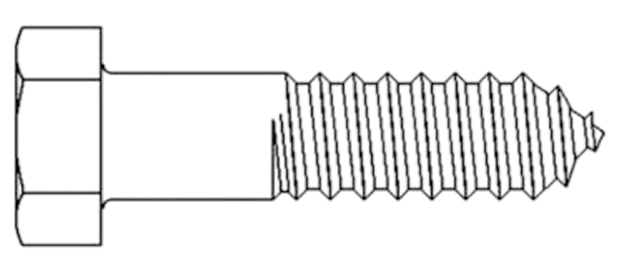

Hex Lag Screws »

Hex lag screws are commonly used for fastening wood pilings, dock timbers, and connecting steel to timber in marine construction. Manufactured up to 1-1/2″ in diameter with custom lengths available, these heavy-duty fasteners deliver strong holding power and long-term durability, ideal for structural connections exposed to moisture, salt, and tidal conditions.

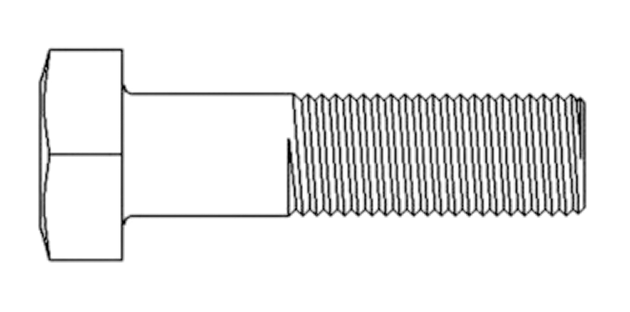

Square Head Bolts »

Before hex bolts became the modern standard, square head bolts were the industry norm in timber and dock construction. Today, they remain a preferred choice for traditional restoration projects or where a vintage aesthetic is required. Portland Bolt manufactures square head bolts up to 2″ in diameter, fully galvanized for long service life in marine applications.

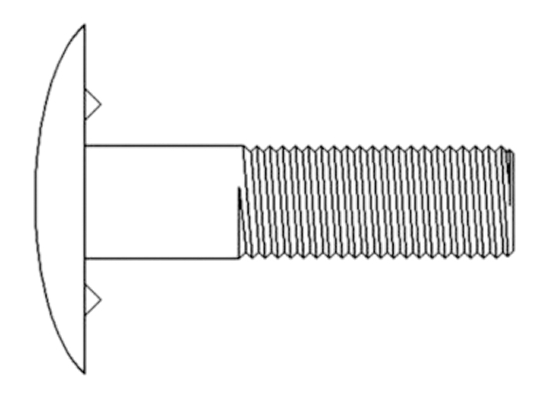

Timber Bolts »

Timber bolts, also known as dome head or economy bolts, have been a mainstay of timber and marine construction for decades. Their oversized, low-profile heads eliminate the need for separate washers, providing a flush finish and increased bearing surface. Portland Bolt produces timber bolts up to 1-1/2″ in diameter, ideal for securing timbers in dock, marina, and seawall construction.

Threaded Rods »

Manufactured for versatility and strength, all thread rods provide reliable fastening in marine construction and repair applications. Commonly used for securing components through wood, steel, or concrete, these fully threaded rods deliver consistent performance in corrosive coastal environments.

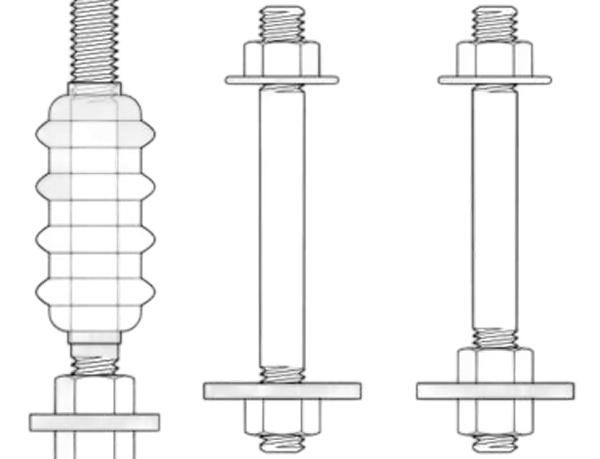

Anchor Rods »

Anchor rods provide critical connections between structural steel and concrete in marine environments. We manufacture both straight and bent configurations in a variety of ASTM grades, with custom threading and embedment lengths. These rods are designed to resist the combined effects of saltwater exposure, vibration, and heavy live loads.

Plates & Washers

Portland Bolt fabricates and supplies a wide range of plates and specialty washers for marine applications. These include:

Plates »

Portland Bolt manufactures custom plates on a precision plasma table up to 1-1/2″ thick, ensuring clean cuts and accurate hole placement. Flat bar and angle assemblies with multiple holes can be produced to meet project specifications.

Malleable Iron Washers »

Malleable cast iron round washers are used in dock and wood construction.

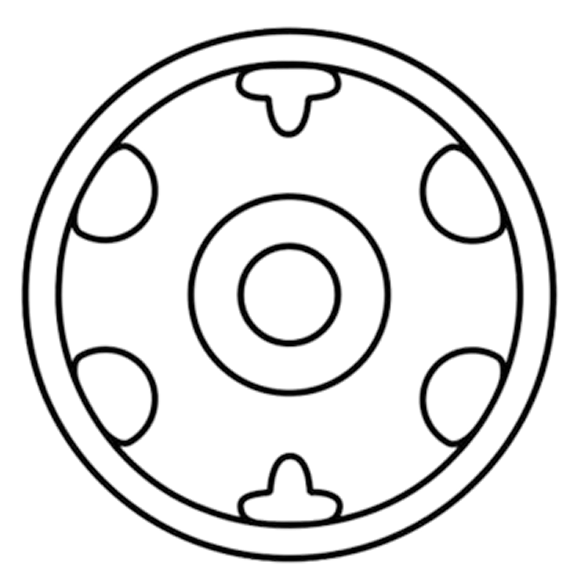

Ogee Washers »

Ogee refers to the curved shape of this large, cast iron washer. They are typically used in dock and timber construction.

Round Plate Washers »

Round plate washers are simply a low carbon steel, oversized cut washer designed to provide a larger bearing surface than an F844 washer.

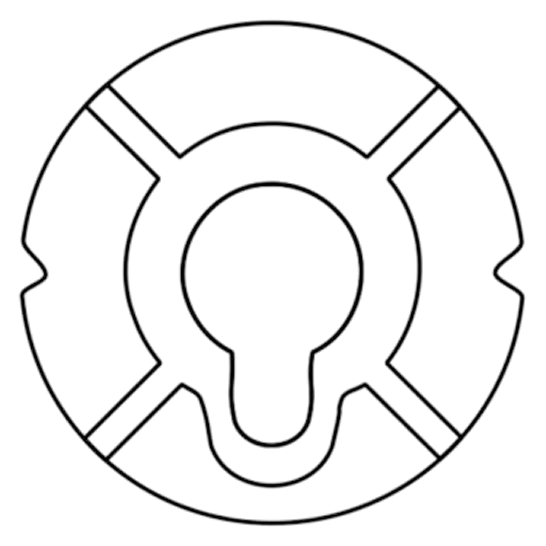

Shear Plates »

Designed to increase the shear strength of wood to wood or wood to steel connections.

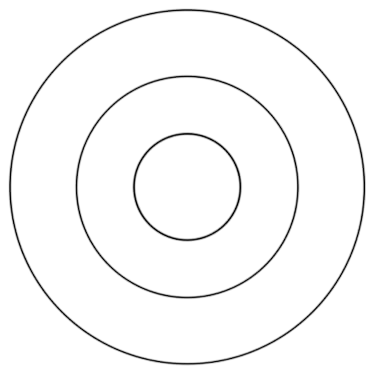

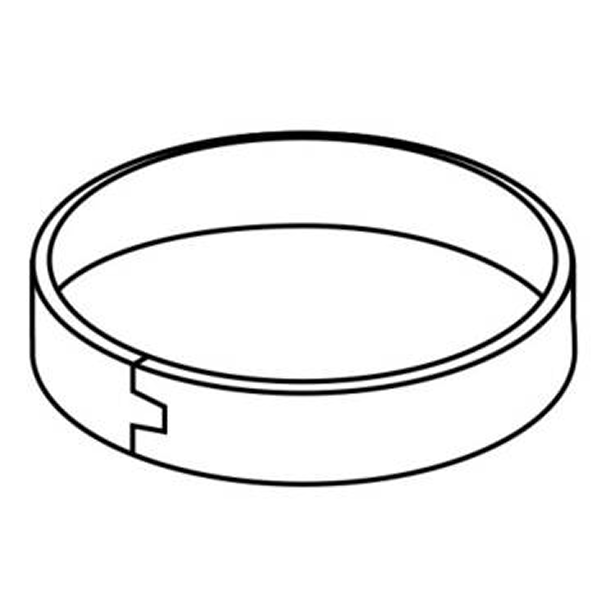

Split Rings »

The split ring wood connector is a device for transmitting loads between two pieces of wood.

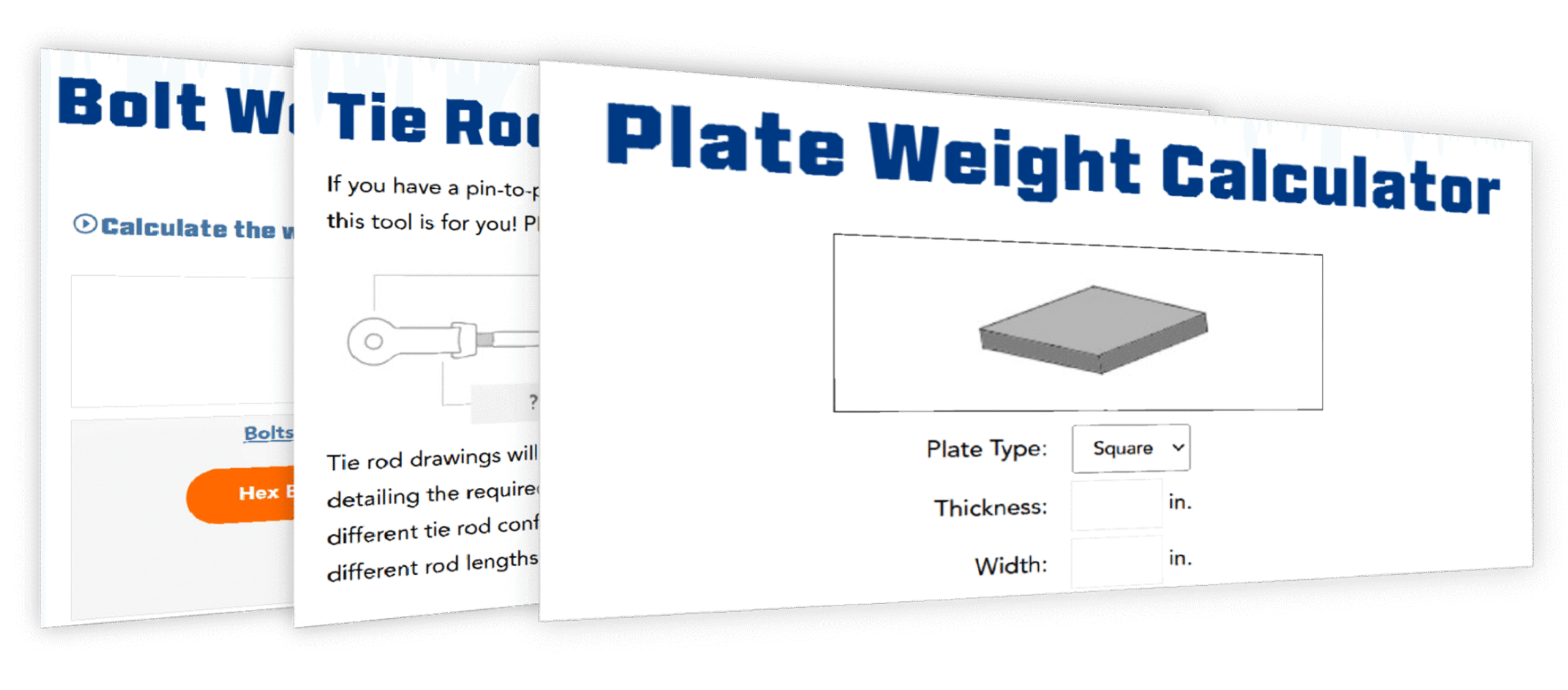

Calculators & Tools

Marine projects demand accuracy and durability at every step. Portland Bolt’s online calculators give engineers and builders, quick, dependable answers for plate weights, bolt loads, and tie rod lengths – keeping your designs efficient and on spec.

Why Marine Contractors Choose Portland Bolt

Marine-Grade Corrosion Protection

In-house galvanizing and stainless steel options provide long-lasting performance in saltwater environments.

Unmatched Manufacturing Capacity

With over 140,000 square feet of production and warehouse space across facilities on both coasts, Portland Bolt delivers fasteners with speed and precision. Our vertically integrated process and massive domestic raw material inventory ensure reliable turnaround, even on tight project schedules.

Experience That Spans Oceans

From local marinas to international port facilities, we understand the unique demands of marine construction.

Engineering Support & Custom Solutions

Our experienced team works directly from project drawings and specifications to ensure fasteners are manufactured to exact requirements.

Certifications & Traceability

Digital certification packages and full domestic traceability provide confidence for government-funded and large-scale projects.

Frequently Asked Questions

The reason that these materials would be preferred over other common fasteners is that they offer greater resistance to rust and corrosion.

When carbon steel fasteners are used in a marine environment, they will typically be hot-dip galvanized to further protect against corrosion. Whether stainless steel or hot-dip galvanized, these features allow the fasteners to be used in various applications where other fasteners would likely rust and corrode.

Another place where you will see marine fasteners used is in the construction and maintenance of marinas. A marina is a dock or basin with moorings and supplies for yachts and small boats. Marinas are exposed to harsh corrosive elements making marine fasteners mandatory.

Seawalls are another place where marine fasteners are necessary. A seawall is constructed where the ocean impacts directly upon the landforms of the coast. The purpose of a seawall is to protect the land from incoming tides, waves, or tsunamis.

Docks, piers, marinas, and seawalls are common marine projects that require galvanized marine fasteners, which provide corrosion resistance and durability.

Hot-dip galvanizing provides corrosion resistance through a process in which zinc bonds to the surface of a fastener. The zinc coating acts as a barrier to prevent rust and corrosion.

The fact that the galvanized coating penetrates the surface of the steel makes the fastener more durable and able to withstand corrosion and maintain its strength and structural integrity over long lengths of time.

Although stainless steel fasteners are commonly used in marine projects, the cost of stainless steel is much higher, making hot-dip galvanizing a more cost-effective option as well as being more readily available.

Hot-dip galvanizing offers an economical, long-term protective coating. This differs from another common coating known as zinc plating (or electroplating), which is a process where zinc is applied by using a current of electricity. This coating is much thinner than hot-dip galvanizing and in general is not specified in outdoor environments, especially marine environments.

Zinc plating is basically an aesthetic finish that could chip off and rust, but the hot-dip galvanized coating bonds and penetrates the surface of the steel and will not chip or flake off over time.

This is a valid question; however, it is unfortunately not easy to answer. There are many different variables to consider, given the countless applications that a galvanized bolt may be used for and the environmental conditions it may be exposed to.

There are many different elements that can make a difference in how long the galvanizing of a bolt will hold up, however, the bolt’s environment is the main factor.

Depending on the climate, the hot-dip galvanized coating will react differently. Common climates requiring a galvanized coating include rain, snow, a marine environment, or even high heat, which results in prolonged sun exposure.

The application of the bolt is also a major factor. For example, a bolt may be used to hold wooden members together above a body of water, however, the same structure may have bolts which are completely submerged in water.

Since one environment is never equal to another, there isn’t any real way to determine how long the galvanizing will last. What we do know is that a galvanized fastener will withstand corrosion much longer than a bolt without any coating.

According to the American Galvanizers Association, galvanized steel “corrodes at a rate of 1/30 of bare steel in the same environment.” The American Galvanizers Association has a Zinc Coating Life Predictor on their website that you may find useful.

Timber bolts are used due to their large round head, which has a low profile so they will not stick up posing a potential hazard. This comes into play when used on docks where people walk. The large, round head also eliminates the need for a malleable iron washer.

Another common marine fastener that Portland Bolt manufactures is what is commonly referred to as float rods. Float rods are long rods with threads on each end. Float rods are used to connect sections of a dock, also known as a floating dock.

Anchor bolts are used for bollards and marine fender systems. All of the marine fasteners that Portland Bolt manufactures are stainless steel or hot-dip galvanized, which is performed in-house.

Galvanizing threaded fasteners requires a specially designed galvanizing line. General-purpose galvanizers may not have centrifuge systems necessary to remove excess zinc from the threads potentially preventing a nut from threading onto the fastener.

Portland Bolt’s unique system developed specifically for threaded fasteners ensures quality threads and a trouble-free nut fit.

PROJECT AT A GLANCE

Ocean Cay Reserve Bahamas

PRODUCTS USED:

- Products: all thread rods headed anchor bolts heavy hex nuts hardened washers

- Grades: A307 Grade A F1554 Grade 36 F1554 Grade 55 SS316 A563 Grade A F436 A194 Grade 2H

- Diameters: 5/8″ to 3/4″

- Lengths: 8″ to 72″

- Finishes: hot-dip galvanized plain black

The Ocean Cay Marine Reserve is a new 5-Star Resort in the Bahamas which consists of cabanas, yacht clubs, food courts, tiki bars, and towers. The job site has more than 100 hurricane engineered buildings designed for the high winds that the area sees every fall. The project required galvanized and stainless steel bolts because of the corrosive environment of the island.

Portland Bolt manufactured the 5/8″ and 3/4″ diameter galvanized F1554 headed anchor bolts required for this job. We were able to provide multiple shipments outside of the United States on time and with all of the international required paperwork. In addition to the headed bolts, Portland Bolt also manufactured the stainless and galvanized cut to length all thread rods. Next time your project, international or domestic, requires anchor bolts or rods, contact one of our sales representatives.