Heading Bolts and Why it Matters

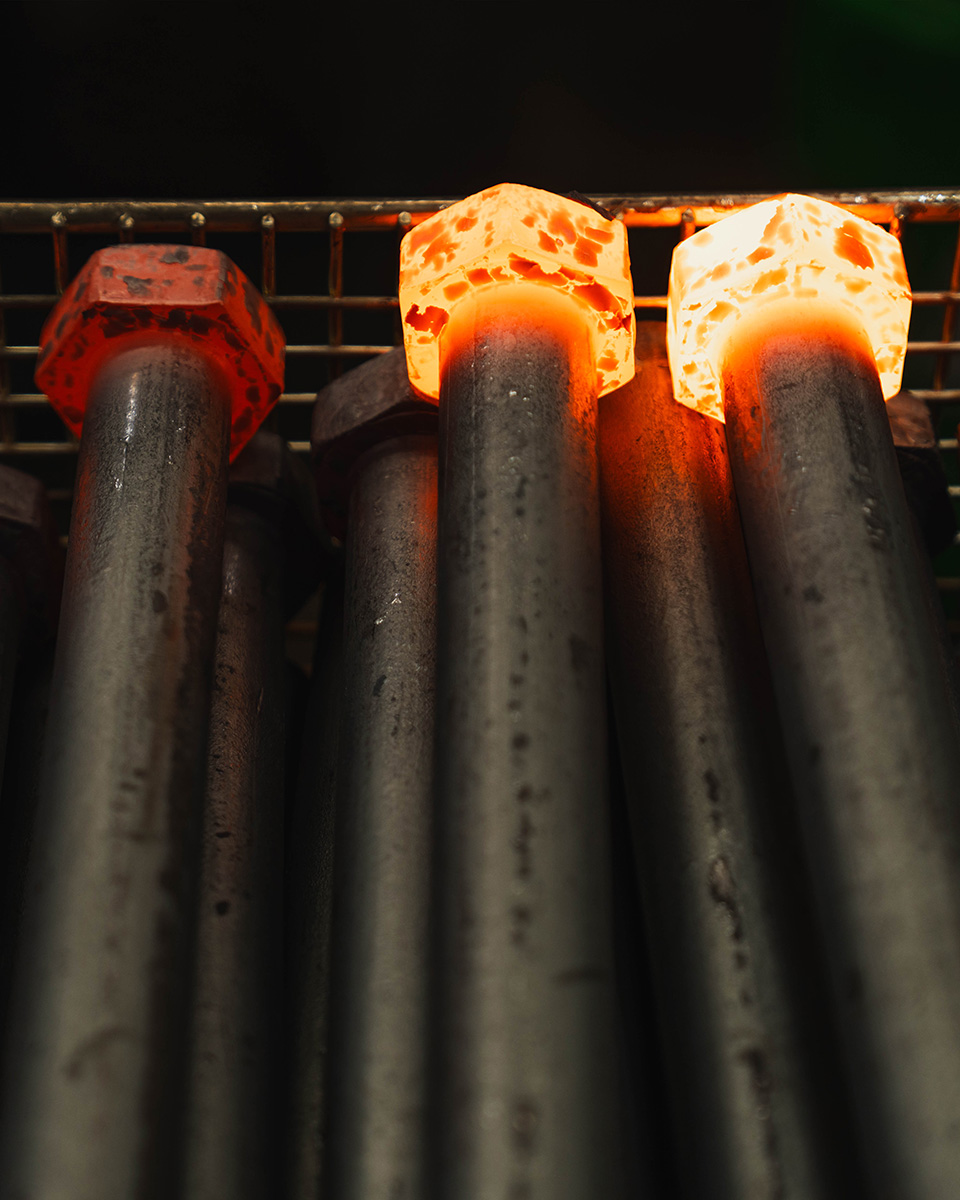

Heading is one of the most critical processes in bolt manufacturing. Portland Bolt uses National Upsetters to hot-forge heads onto bolts, heating the end of a round bar via induction and compressing the steel in a plunger die to create the head configuration.

A properly forged head provides a bearing surface with strength, durability, and reliability under load. It ensures that the bolt head shape (hex, heavy hex, square, etc.) can withstand wrench or tooling torque, distribute forces properly, resist bending and shear, and perform well in demanding conditions.

Portland Bolt’s Heading Capabilities

- We can forge bolt heads on diameters from ½″ up to 2½″ using upsetters.

- Common head styles include:

- We also offer custom head styles and custom tooling, including forging your company name or logo into the head.

The Heading Process: How It Works

Here are the main steps in heading (hot forging) as done at Portland Bolt and in general:

- Material Preparation

Round bar stock is selected per the required material and diameter. The end portion where the head will be formed is considered in the length, with additional material allocated so that, when forged, the bolt meets the final required overall length. - Heating via Induction

The bar end is heated (induction heating) to a temperature high enough to make the metal malleable for hot forging. - Upsetting / Forging the Head

The heated end is placed in the header/upsetter. A plunger compresses the hot material, displacing it to form the head shape. This is a “hot heading” operation. - Heat Treatment / Strengthening (if required)

For high-strength bolts or when required by specification, parts are quenched and tempered after heading to achieve mechanical properties. - Secondary Finishes

If required, operations like surface cleaning (e.g. wheelabration), hot-dip galvanizing, or roto blasting are completed.

What to Consider / Why It’s Important

- The grain flow is preserved during forging, resulting in improved mechanical strength.

- Head shapes and styles matter for applications: e.g., heavy hex for structural bolts, countersunk for flush surfaces, dome or timber heads for aesthetic or specific form-fit uses.

- The diameter and thickness of the bolt head affect torque distributions, wrench selection, bearing areas, and overall load distribution.

- Material choice, heat treatment, and correct process (hot vs cold heading) affect not only strength but also fatigue resistance, dimensional tolerance, and durability.