Built for Performance in Highway Applications

All Portland Bolt fasteners are produced across our four U.S. manufacturing facilities totaling more than 270,000 square feet of production space, where forging, threading, testing, and galvanizing are performed in-house for total quality and traceability. Our U.S.-made steel inventory spans diameters from 1/2″ to 3-1/2″ and multiple material grades, ensuring compliance with DOT and federal procurement standards, including the Buy American Act and Build America, Buy America (BABA) provisions. The result is consistent strength, reliability, and performance in critical infrastructure applications.

For decades, Portland Bolt has been a cornerstone in that foundation – manufacturing 100% domestic, fully traceable fasteners for the nation’s highways and bridges.

With 4 manufacturing facilities across the United States totaling more than 270,000 square feet of production space, Portland Bolt delivers the capacity and reach to support major infrastructure projects nationwide.

Our Northwest and Southeast plants house state-of-the-art hot-dip galvanizing operations, offering a full suite of galvanizing services on both coasts.

Every process, from forging and threading to testing and inspection, is performed in-house for full control over quality, traceability, and lead times.

All fasteners meet ASTM, SAE, and AASHTO specifications, ensuring compliance with every DOT standard and Build America, Buy America provision.

From bridge anchor systems and guardrail bolts to tie rods and barrier pins, Portland Bolt fasteners are built for performance in the toughest environments.

They support the structures that keep America moving – safely, reliably, and for generations to come.

At Portland Bolt, every product is more than steel – it’s a promise of quality, integrity, and American craftsmanship.

For your next highway or bridge project, contact Portland Bolt.

Commonly Used Products

Barrier Pins »

Barrier pins are used to connect precast concrete barriers and anchor barriers to the roadway. Portland Bolt manufactures these pins in various configurations and finishes to meet individual state DOT specifications.

Hex Bolts »

Hex head bolts are among the most widely used fasteners in construction. We produce hex bolts up to 2-1/2 inches in diameter in multiple ASTM grades, with domestic nuts and washers available for complete assemblies.

Structural Bolts »

Heavy hex structural bolts meet ASTM F3125 Grades A325 and A490 and are designed for high-strength steel connections. Diameters range from 1/2 inch to 1-1/2 inches, suitable for bridges, overpasses, and structural steel applications.

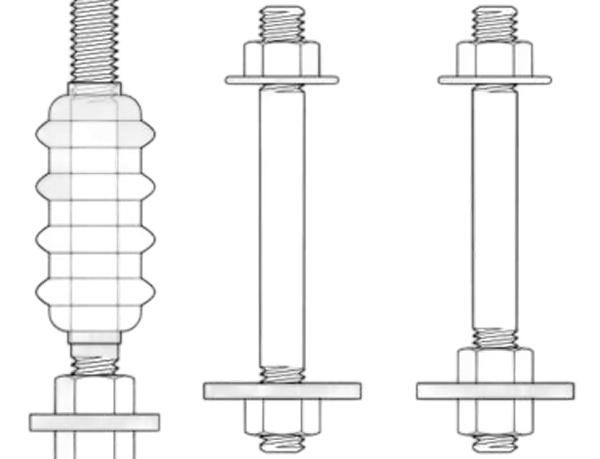

Anchor Rods »

Anchor rods are available in numerous configurations and grades to secure columns, poles, and structural supports to concrete foundations. We produce custom assemblies complete with washers, nuts, and templates.

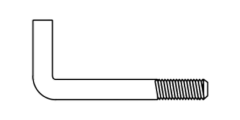

90° Anchor Bolts »

Right-angle bend anchor bolts are a standard solution for connecting steel to concrete. They are manufactured to project specifications and hot-dip galvanized in-house for long-term corrosion protection.

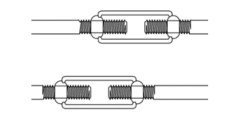

Tie Rods »

Tie rod assemblies provide bracing in large structural systems, including bridge installations. Assemblies can include turnbuckles, clevises, and threaded rods, all machined and finished in-house for precise fit and alignment.

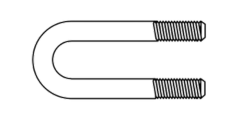

Round U-Bolts »

Custom round bend U-bolts are available from 1/2 inch to 4 inches in diameter, produced to virtually any ASTM specification. They are used in roadway supports, pole mounting, and pipe hanging applications.

Plates »

Our plasma table can produce anchor plates, washers and templates up to 1-1/2″ thick, with multiple holes, to match exact project blueprints and load requirements.

Guardrail Bolts »

Guardrail bolts are engineered for roadside safety systems and manufactured to ASTM A307 Grade A. Each bolt meets the strength and mechanical requirements outlined by federal and state specifications.

Double Recessed Nuts »

ASTM A563 Grade A double recessed hex nuts (DR nuts) are designed for use in guardrail and post bolt assemblies. Portland Bolt supplies these specialized nuts for highway safety and guardrail applications.

Why Highway Contractors Choose Portland Bolt

DOT-Approved and Specification-Compliant

Portland Bolt manufactures fasteners that meet stringent ASTM, SAE, and AASHTO standards for bridge and highway construction. Our team works closely with DOT agencies nationwide to ensure every product meets federal and state compliance requirements.

Unmatched Manufacturing Capacity

With extensive domestic steel inventory and a vertically integrated process, Portland Bolt can respond quickly to large-scale and time-sensitive projects. Our in-house production and galvanizing capabilities ensure consistent lead times, dependable quality, and exceptional accuracy across every product.

Engineering and Submittal Support

Our specialists assist with AASHTO-to-ASTM conversions, submittal documentation, and material substitutions. We collaborate with contractors, engineers, and inspectors to ensure every fastener is built to spec and ready for inspection.

Certifications & Traceability

Digital certification packages and full domestic traceability provide confidence for government-funded and large-scale projects.

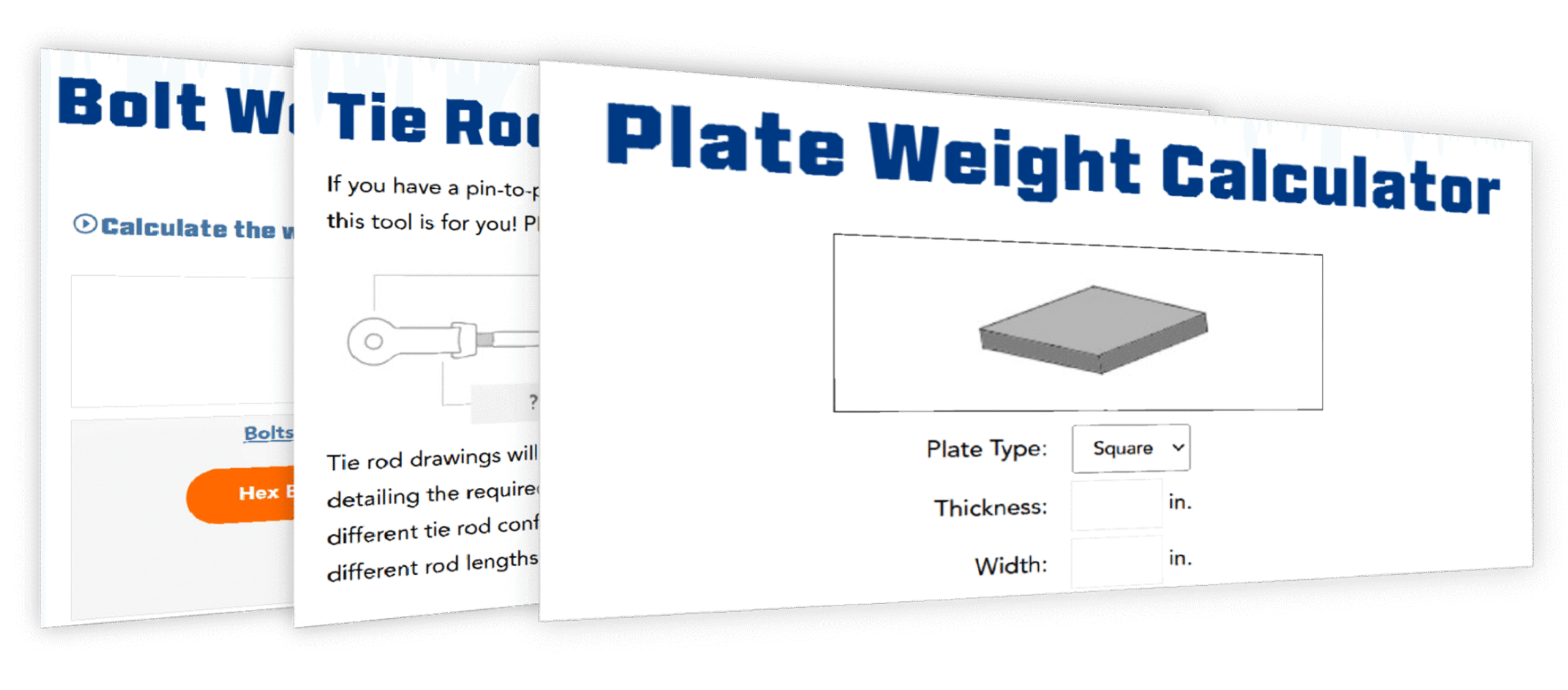

Calculators & Tools

Accurate specifications are critical in highway and bridge construction. Portland Bolt provides a suite of online calculators to support engineers, contractors, and project managers working on guardrails, sign structures, and concrete anchors. From estimating plate weights to calculating bolt loads and anchor rod lengths, these tools help you plan efficiently, meet DOT requirements, and keep every project moving safely and on schedule.

PROJECT AT A GLANCE

PROJECT AT A GLANCE